gary808

- 6

- 6

- TL;DR

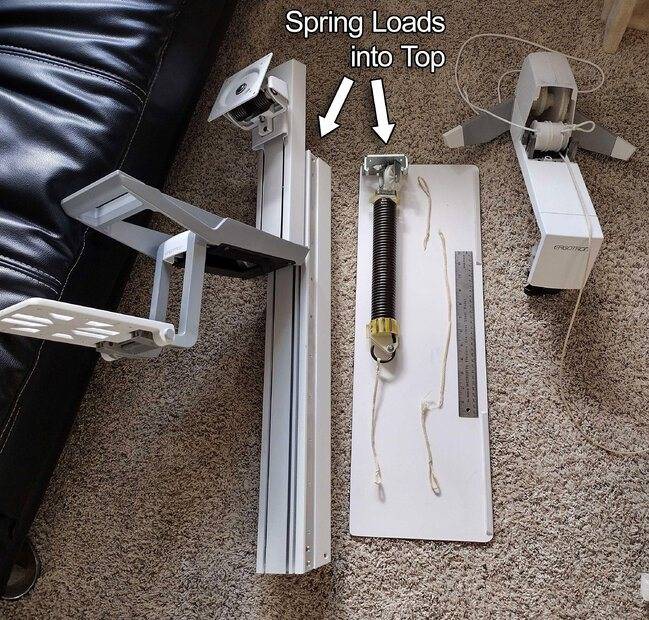

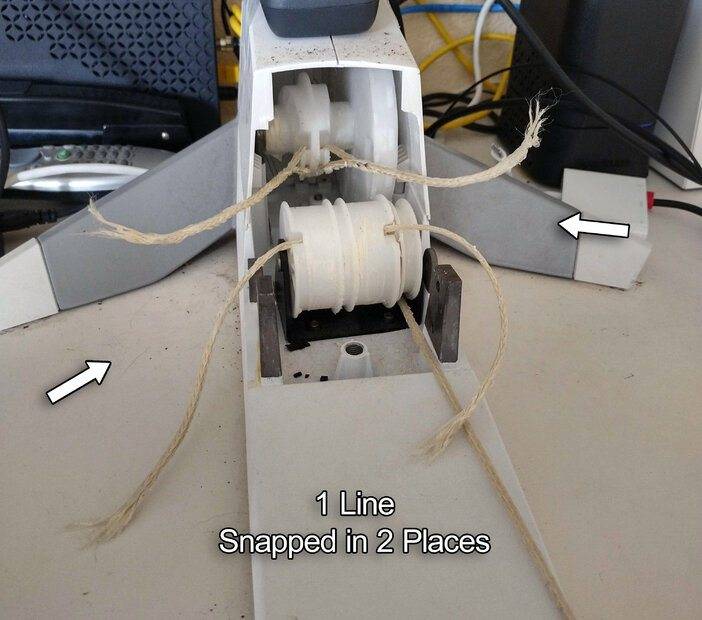

- A Stand/Sit workstation is tensioned by internal nylon ropes. When one breaks, the internal spring snaps back into a rest state. But how did one rope break in two places simultaneously?

I'm attempting to repair my Ergotron Workfit station. After taking apart, I discovered the problem. A single nylon rope split, releasing the spring's tension. Because it is past the warranty, the manufacturer is recommending I toss the whole assembly and buy a new $650 one. Doesn't seem the sensible thing to do over a $1 rope.

You can see from these photos, there are a total of 3 nylon ropes; one from the spring's base, one through the lower center spindle, and one longer rope just behind and to the right of the lower spindle. I'm sure that one extends up through the wheel next to the spring.

I cannot find any mechanical specs on how these 3 ropes come together and I'm hoping someone here can illustrate so I can reassemble with the new 100lbs, nylon cord.

I just can't imagine how one rope can snap in two places simultaneously. Normally once one section breaks, it relieves all the tension in the remaining cord. There'd be no second break in the same rope.

You can see from these photos, there are a total of 3 nylon ropes; one from the spring's base, one through the lower center spindle, and one longer rope just behind and to the right of the lower spindle. I'm sure that one extends up through the wheel next to the spring.

I cannot find any mechanical specs on how these 3 ropes come together and I'm hoping someone here can illustrate so I can reassemble with the new 100lbs, nylon cord.

I just can't imagine how one rope can snap in two places simultaneously. Normally once one section breaks, it relieves all the tension in the remaining cord. There'd be no second break in the same rope.