jsh111

- 8

- 2

- TL;DR Summary

- This is a steam engine idea I am freely sharing. The idea is that large quantities of steam stored is dangerous, therefore generate it on demand for a piston engine. Please criticize/ tear it apart

Background: In my opinion the next decade has great potential for difficult circumstances for worldwide. I have been obsessed with coming up with a small electrical power generation system (minimum 500 watt, goal is 1kW) for charging batteries during disaster relief situations where refined fuels are scarce, but biomass is relatively abundant.

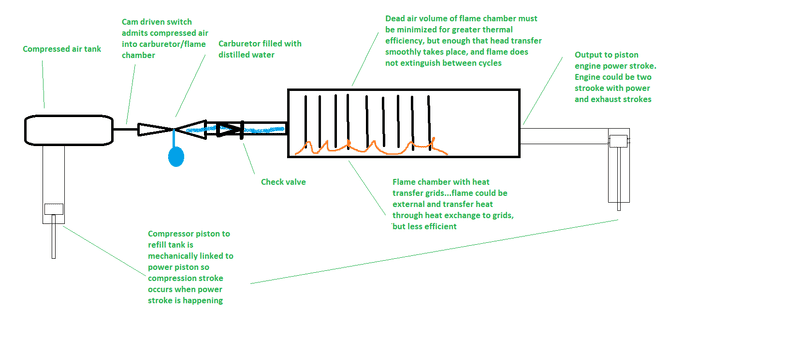

The attached block diagram is a rudimentary high level design for a steam engine that generates steam on demand for each power cycle, rather than storing steam in a boiler, which presents numerous safety concerns. It is inspired by the Brayton thermodynamic cycle, and indeed, I believe the above could be run on compressed air alone, if designed sufficiently efficient (minimizing dead volume in the burn chamber is critical).

Theory of operation: A fine water mist is generated by running compressed air through a carburetor filled with distilled water. The compressed air chamber is opened briefly by either a cam, or electronic sensor valve. compressed air mixes with a fine water mist via the carburetor, which is then pushed through a check valve into a burn chamber. This burn chamber is filled with numerous stainless steel grids to transfer heat to the small water droplets, and generate steam. The introduction of water (an already compressed fluid) to the air effectively increases the density of the working fluid (rather than just using compressed air alone). As the water mist and cool air contact the metallics grids, heat is transferred, causing the water to transition to steam and greatly expand. This expansion drives a power piston, which is mechanically linked to a compression piston that refills the compressed air chamber for the next cycle.

numerous improvements could be made:

1) Exhaust steam could be thermally recycled in a manner similar to the Ericcson cycle

2) rather than a carburetor/venturi, a fuel injection system could be employed to pre-vaporize the water, or perhaps an ultrasonic transducer to generate a water "fog" prior to the compressed air introduction

3) The flame chamber's volume is minimized by having a high density of metal grid/ volume

4) the flame could be external to the chamber in the case of unclean fuels, reducing efficiency, but allowing for much greater fuel flexibility and maintainability of the system

The attached block diagram is a rudimentary high level design for a steam engine that generates steam on demand for each power cycle, rather than storing steam in a boiler, which presents numerous safety concerns. It is inspired by the Brayton thermodynamic cycle, and indeed, I believe the above could be run on compressed air alone, if designed sufficiently efficient (minimizing dead volume in the burn chamber is critical).

Theory of operation: A fine water mist is generated by running compressed air through a carburetor filled with distilled water. The compressed air chamber is opened briefly by either a cam, or electronic sensor valve. compressed air mixes with a fine water mist via the carburetor, which is then pushed through a check valve into a burn chamber. This burn chamber is filled with numerous stainless steel grids to transfer heat to the small water droplets, and generate steam. The introduction of water (an already compressed fluid) to the air effectively increases the density of the working fluid (rather than just using compressed air alone). As the water mist and cool air contact the metallics grids, heat is transferred, causing the water to transition to steam and greatly expand. This expansion drives a power piston, which is mechanically linked to a compression piston that refills the compressed air chamber for the next cycle.

numerous improvements could be made:

1) Exhaust steam could be thermally recycled in a manner similar to the Ericcson cycle

2) rather than a carburetor/venturi, a fuel injection system could be employed to pre-vaporize the water, or perhaps an ultrasonic transducer to generate a water "fog" prior to the compressed air introduction

3) The flame chamber's volume is minimized by having a high density of metal grid/ volume

4) the flame could be external to the chamber in the case of unclean fuels, reducing efficiency, but allowing for much greater fuel flexibility and maintainability of the system

Last edited by a moderator: