Mike Gaffer

- 24

- 0

- TL;DR Summary

- Need to select optics path and parts for building a high resolution laser scanner on a 2D plane.

Objectives:

- best path for optics needed to focus and "draw"/project a high resolution image onto a workspace around 500mm square (for a Laser Direct Imaging machine)

- where to cost effectively purchase or make the optics necessary to build a prototype

The problem:

I need to project a high resolution image onto photoresist (photographic paper/film).

The film is sensitive to UV in the 300-440nm spectrum. Therefore, I was considering a Violet (405nm) or Blue (450nm) laser.

The film is used for PCB (circuit board) etching - I'm not sure of the laser power, or exposure time/passes with the laser, needed to expose, but not overexpose the film. I ordered film and a 1watt laser diode at 405nm (multimode) off Alibaba.

The area needs to scan 500mm x 500mm (larger would be better, but may be too expensive).

The focusing and scanning accuracy has to be 0.08mm or better, as in be able to draw lines accurately and repeatedly on the film being exposed.

I'm considering using a galvometer, like for a laser light show, and ordered a $90 kit off eBay to test.

Questions:

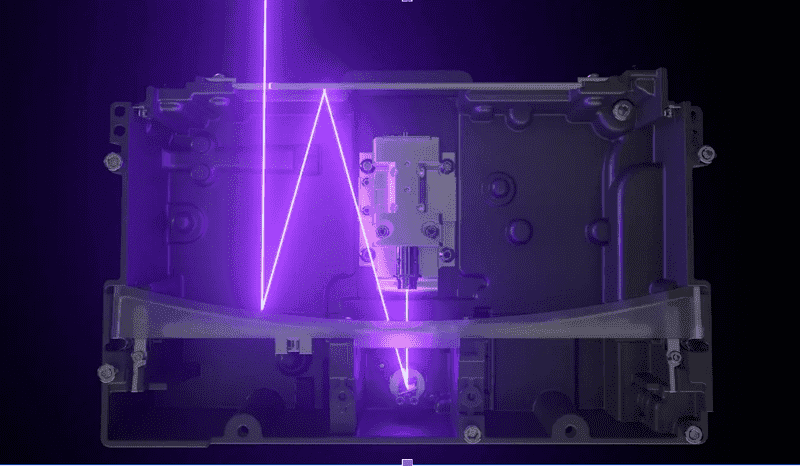

- How would I go about selecting the best optical path so I get a nice, tight, controllable, focused beam to form my scan or image? I notice the SLA 3D printer, "Form Labs" uses a laser, focused on a galvometer, bouncing off a large flat first surface mirror, and a parabolic (focusing?) mirror, before it is projected over a build area of around 300x300mm (below).

- Is this complex path needed?

- How would I go about doing these calculations?

- where could I find or build a parabolic surface mirror like that if necessary on a budget?

- Is the multimode laser okay for this?

I also considered a DLP (digital light processor) chip and UV laser (like a laser video projector), however I dont think the resolution would be high enough. The highest resolution projection of light I need will be 0.09mm. So, if we assume 500mm @ 0.09mm resolution, this = ~5500 px, or 30,250,000 "pixels." - therefore I've ruled out a DLP chip with a UV laser, which typically runs 1920px x 1080px.

I've also considered scanning in 2D, the laser beam on the X axis, and moving the workpiece on the Y, but I think this would add complexity.

Can anyone point me in the right direction for design ideas? where to source parts? starting calculations or CAD programs/calculators?

Thank you in advance!

- best path for optics needed to focus and "draw"/project a high resolution image onto a workspace around 500mm square (for a Laser Direct Imaging machine)

- where to cost effectively purchase or make the optics necessary to build a prototype

The problem:

I need to project a high resolution image onto photoresist (photographic paper/film).

The film is sensitive to UV in the 300-440nm spectrum. Therefore, I was considering a Violet (405nm) or Blue (450nm) laser.

The film is used for PCB (circuit board) etching - I'm not sure of the laser power, or exposure time/passes with the laser, needed to expose, but not overexpose the film. I ordered film and a 1watt laser diode at 405nm (multimode) off Alibaba.

The area needs to scan 500mm x 500mm (larger would be better, but may be too expensive).

The focusing and scanning accuracy has to be 0.08mm or better, as in be able to draw lines accurately and repeatedly on the film being exposed.

I'm considering using a galvometer, like for a laser light show, and ordered a $90 kit off eBay to test.

Questions:

- How would I go about selecting the best optical path so I get a nice, tight, controllable, focused beam to form my scan or image? I notice the SLA 3D printer, "Form Labs" uses a laser, focused on a galvometer, bouncing off a large flat first surface mirror, and a parabolic (focusing?) mirror, before it is projected over a build area of around 300x300mm (below).

- Is this complex path needed?

- How would I go about doing these calculations?

- where could I find or build a parabolic surface mirror like that if necessary on a budget?

- Is the multimode laser okay for this?

I also considered a DLP (digital light processor) chip and UV laser (like a laser video projector), however I dont think the resolution would be high enough. The highest resolution projection of light I need will be 0.09mm. So, if we assume 500mm @ 0.09mm resolution, this = ~5500 px, or 30,250,000 "pixels." - therefore I've ruled out a DLP chip with a UV laser, which typically runs 1920px x 1080px.

I've also considered scanning in 2D, the laser beam on the X axis, and moving the workpiece on the Y, but I think this would add complexity.

Can anyone point me in the right direction for design ideas? where to source parts? starting calculations or CAD programs/calculators?

Thank you in advance!

Last edited: