DaveC426913

Gold Member

- 23,917

- 7,967

- TL;DR Summary

- Looking for a hinge-joint that has the required freedom of movement in a compact and practical design.

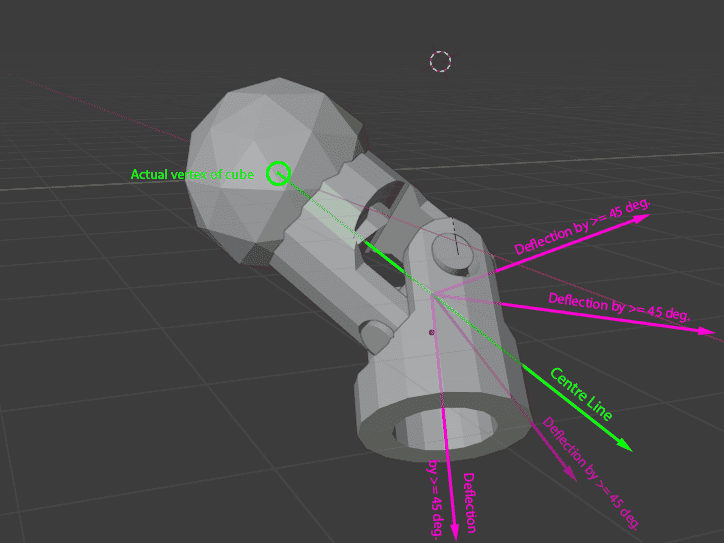

First, a caveat: this is one component of a project, which is difficult to describe without quite a but of digression. If my descriptions seem illogical, it may be because I haven't described the function of the component in its proper context. I assume it will take a little bit of back-and-forth before I'm understood. For those of you who have known me online, this is a revisitation of my tesseract project.I'm designing a wireframe of a ... "cube-like thing" from hollow tubing (may be brass hobby tubing, may be 3D printed). It needs to have joints - actually vertices - that can deflect by at least 45 degrees in any direction.

I have been using universal joints, like they use in automobile drivetrains, but they are not ideal. U-joints are meant to undergo rotation, and mine does not need to. MY problem with the u-joint is that it's bulky. The actual length of the joint mechanism (vertex) takes up more of the cube's edge that I can afford.

What I want is a compact design. By that I mean I'm not concerned about the width, just the length that the parts of the joints take up (independent of scale).

Every vertex is a sphere with 4 (four) of these universal joints merging from it equally. (only one shown here).

I am looking for a joint design that:

- provides a deflection of at least 45 degrees in any direction

- is as compact as possible (i.e. short along its primary axis)

- provides minimum play (eg. a piece of string provides unlimited deflection but can just as easily collapse)

- is robust (string for example, will break over time)

- can be practically constructed

I've tried several designs - everything from ball-and-socket joints** to string to springs.

**interestingly, a ball-and-socket joint can't deflect by 45 degrees at all.

Looking for suggestions.

I have been using universal joints, like they use in automobile drivetrains, but they are not ideal. U-joints are meant to undergo rotation, and mine does not need to. MY problem with the u-joint is that it's bulky. The actual length of the joint mechanism (vertex) takes up more of the cube's edge that I can afford.

What I want is a compact design. By that I mean I'm not concerned about the width, just the length that the parts of the joints take up (independent of scale).

Every vertex is a sphere with 4 (four) of these universal joints merging from it equally. (only one shown here).

I am looking for a joint design that:

- provides a deflection of at least 45 degrees in any direction

- is as compact as possible (i.e. short along its primary axis)

- provides minimum play (eg. a piece of string provides unlimited deflection but can just as easily collapse)

- is robust (string for example, will break over time)

- can be practically constructed

I've tried several designs - everything from ball-and-socket joints** to string to springs.

**interestingly, a ball-and-socket joint can't deflect by 45 degrees at all.

Looking for suggestions.