Redron

- 8

- 4

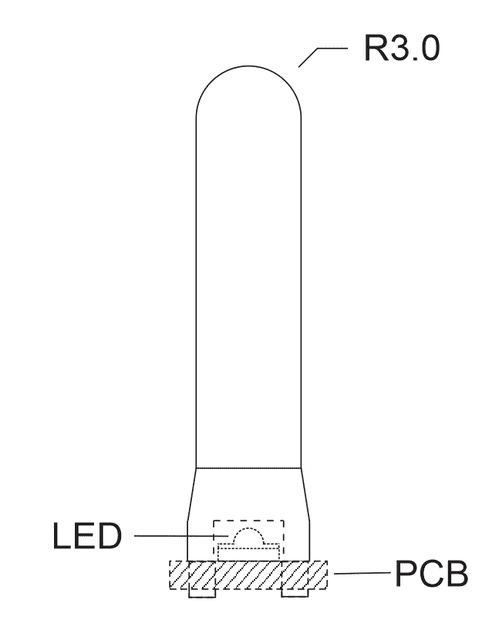

I am trying to design an acrylic light pipe that has a 3W power red LED input with 60 degree beam angle.

I need a reasonably collimated exit light beam or at least a narrow angle output.

What I'd like to know is - what is the optimum shape of the exit end of the light pipe to produce the narrowest beam?

The first iteration is with a hemispherical exit. but I suspect that might produce total internal reflection for shallow angle rays at the edge and perhaps a wide angle beam.

Can anyone please suggest a better shape? Flat or convex may well be better, but I cannot afford a ray tracing program to verify this.

I need a reasonably collimated exit light beam or at least a narrow angle output.

What I'd like to know is - what is the optimum shape of the exit end of the light pipe to produce the narrowest beam?

The first iteration is with a hemispherical exit. but I suspect that might produce total internal reflection for shallow angle rays at the edge and perhaps a wide angle beam.

Can anyone please suggest a better shape? Flat or convex may well be better, but I cannot afford a ray tracing program to verify this.

Last edited: