- #1

adil_mohammad

- 12

- 0

- TL;DR Summary

- Looking for a plastic material for prototyping a design. Needs to be durable and cheap for mass production.

Hello everyone,

First of all a very happy new year to everyone! And a big thank you to all the people who contribute to this forum, I have learned so much from here.

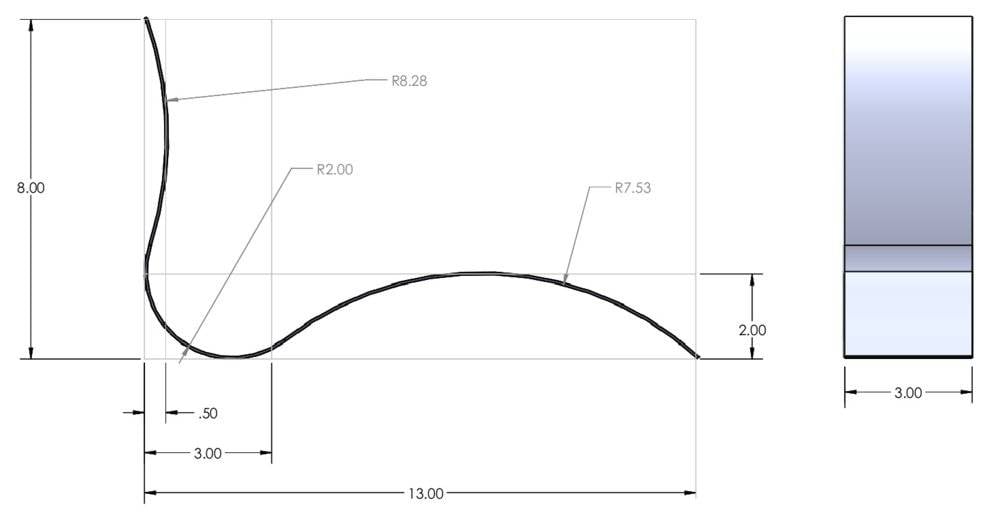

I am prototyping a design for a part that will be used in a consumer product. I am in the early stages of researching materials. The design can be built with spring steel however I was wondering if there are any plastics out there that have similar properties. Most importantly I am interested in flexural strength at different weights. If I were to apply weight ranging from 125-250 lbs, I need it to bend but then return to original position, like a flat spring almost. The closest thing I have come across is fiber-reinforced plastic; such as glass filled nylon or some type of carbon filament in epoxy. Cost and ease of manufacturing is also an important factor so it can't be too high tech a material. I am pretty stuck right now so any guidance and direction would be greatly appreciated. I have included a drawing to help visualize it, the weight would be applied to the curve that sits on the x-axis and as a result the y curve would move laterally, that movement is very necessary, that's what makes the whole thing work, the figures are in inches. Thank you.

First of all a very happy new year to everyone! And a big thank you to all the people who contribute to this forum, I have learned so much from here.

I am prototyping a design for a part that will be used in a consumer product. I am in the early stages of researching materials. The design can be built with spring steel however I was wondering if there are any plastics out there that have similar properties. Most importantly I am interested in flexural strength at different weights. If I were to apply weight ranging from 125-250 lbs, I need it to bend but then return to original position, like a flat spring almost. The closest thing I have come across is fiber-reinforced plastic; such as glass filled nylon or some type of carbon filament in epoxy. Cost and ease of manufacturing is also an important factor so it can't be too high tech a material. I am pretty stuck right now so any guidance and direction would be greatly appreciated. I have included a drawing to help visualize it, the weight would be applied to the curve that sits on the x-axis and as a result the y curve would move laterally, that movement is very necessary, that's what makes the whole thing work, the figures are in inches. Thank you.