- #1

ChrisEffinSmi

- 16

- 0

So, a coworker approached me today with a 'simple problem' to solve, looking to sanity-check a design choice.

Much to my dismay, I had no idea how to approach it. Worse, google had no straight-forward answers either, and any formulae I did find seemed circular.

This seems too simple to require CFD or the like, and I feel like an obvious approach should jump out of standard equations, but I've been fussing with it for half a day to no avail.

Even just a point in the right direction would be much appreciated.

1. Homework Statement

A stainless steel tube section of length L (say, 10mm) and diameter D (say 5mm) has 500 standard liters per minute of Nitrogen gas (N2) flowing through it (so a mass flow of ~0.01042 kilograms per second, if I did my math right). What is the pressure drop across this tube section?

Temperature change is unknown, so unless that can be calculated or approximated, I guess we can assume an isothermic process? (I would think very little temperature change could occur over so short a distance anyway, but what do I know, I can't even start this problem...).

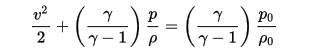

Bernoulli's compressible flow equation (simplified) seems like it would be useful here, but its application escapes me, particularly when trying to extract the velocity from mass flow (how can I divide out density when gas density changes with pressure?)

https://en.wikipedia.org/wiki/Bernoulli's_principle#Compressible_flow_in_fluid_dynamics

I got nothin'. =[

Much to my dismay, I had no idea how to approach it. Worse, google had no straight-forward answers either, and any formulae I did find seemed circular.

This seems too simple to require CFD or the like, and I feel like an obvious approach should jump out of standard equations, but I've been fussing with it for half a day to no avail.

Even just a point in the right direction would be much appreciated.

1. Homework Statement

A stainless steel tube section of length L (say, 10mm) and diameter D (say 5mm) has 500 standard liters per minute of Nitrogen gas (N2) flowing through it (so a mass flow of ~0.01042 kilograms per second, if I did my math right). What is the pressure drop across this tube section?

Temperature change is unknown, so unless that can be calculated or approximated, I guess we can assume an isothermic process? (I would think very little temperature change could occur over so short a distance anyway, but what do I know, I can't even start this problem...).

Homework Equations

Bernoulli's compressible flow equation (simplified) seems like it would be useful here, but its application escapes me, particularly when trying to extract the velocity from mass flow (how can I divide out density when gas density changes with pressure?)

https://en.wikipedia.org/wiki/Bernoulli's_principle#Compressible_flow_in_fluid_dynamics

The Attempt at a Solution

I got nothin'. =[