YehiaMedhat

- 21

- 3

- Homework Statement

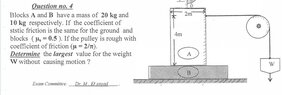

- Blocks A and B have a weights of 200N and 100N respectively. If the coefficient of static friction is the same for the ground and blocks ##\mu_s =0.5##. If the pulley is rough with coefficient of friction ##\mu =\frac{2}{\pi}##. Determine the the largest value of the weight W without causing motion.

- Relevant Equations

- ##F_s=\mu_s*N##

##\sum{}^{} F_y =0##

##\sum{}^{} F_x =0##

First, I assumed that the tension in the rope connected to the block A equals the static friction ##\sum{}^{} F_x =0 \rightarrow T=N_A*0.5=100N##, then the W weight or force equals to the tension in the pulley and the tension T ##W=100+\frac{2W}{\pi} \rightarrow W=275.2N##

It's the first problem I have with friction in the pulley so was that correct? I feel uncomfortable with it.

It's the first problem I have with friction in the pulley so was that correct? I feel uncomfortable with it.