Malamala

- 345

- 28

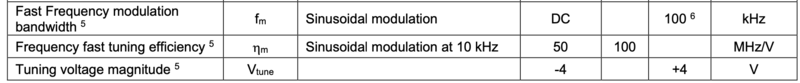

Hello! I am trying to understand the properties of a laser I am trying to lock to a cavity. I would like to adjust its wavelength in order to achieve the locking. I attached below a part of the properties that I am confused about (I emailed the company, too, but I haven't heard back yet). I understand that the locking (in my case PDH locking) works by modulating the laser frequency and using the sidebands to calculate the derivative of the signal and you lock it to the zero of the derivative (I apologize in advance if the naming in this table is not general, in which case I will just wait for the company to reply).

Is "Fast Frequency modulation bandwidth" the frequency at which the laser can be modulated, which means that the servo must produce a dither signal below 100 kHz? I am a bit confused as I found some stuff online saying that "bandwidth" refers actually to how often the feedback is sent to the laser (i.e. how often the laser frequency is corrected to match the cavity), not to the actual modulation frequency.

I am not sure what "Frequency fast tuning efficiency" is, so any advice/reading would be appreciated.

I assume that "Tuning voltage magnitude" is related to "Frequency fast tuning efficiency", but I don't know how.

Any insight into understanding this table would be really appreciated. Thank you!

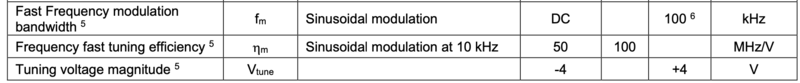

Is "Fast Frequency modulation bandwidth" the frequency at which the laser can be modulated, which means that the servo must produce a dither signal below 100 kHz? I am a bit confused as I found some stuff online saying that "bandwidth" refers actually to how often the feedback is sent to the laser (i.e. how often the laser frequency is corrected to match the cavity), not to the actual modulation frequency.

I am not sure what "Frequency fast tuning efficiency" is, so any advice/reading would be appreciated.

I assume that "Tuning voltage magnitude" is related to "Frequency fast tuning efficiency", but I don't know how.

Any insight into understanding this table would be really appreciated. Thank you!

)

) but thanks!

but thanks!