Malamala

- 345

- 28

Hello! I have a laser that I want to mode match to a bow tie cavity. For my setup I only care about power amplification inside the cavity, not about the actual frequency that gets amplified. So the cavity itself is not super stable, but I want to use a servo to control the laser wavelength such that the laser follows the cavity, such that it is always mode matched and hence I get amplification.

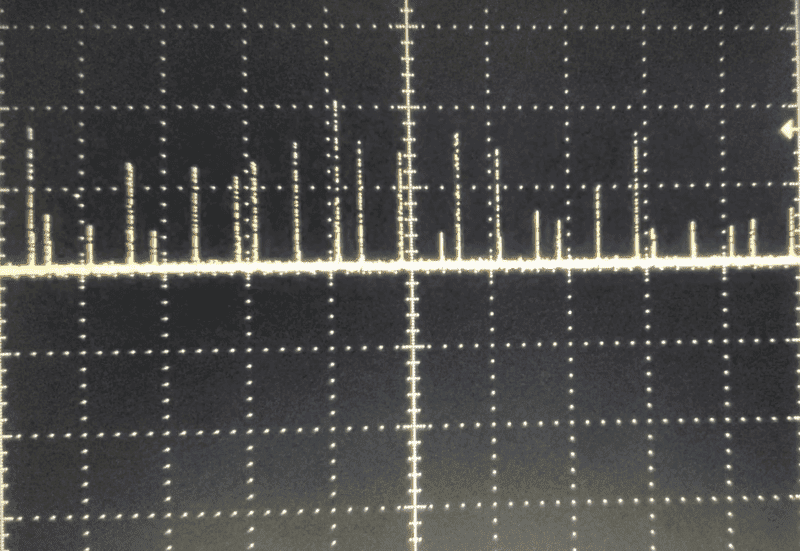

The cavity has a linewidth of 25 kHz and the laser has a linewidth of 5 kHz (at 1064 nm and 20 W power). Currently I am trying to align the cavity and I am scanning the laser frequency while adjusting the mirrors. I am able to see (by measuring with a diode the transmission from one of the mirrors) the cavity modes (see attached figure), but they look kinda weird. I am pretty sure these are due to amplification inside the cavity, as if I block one of the paths inside the cavity all the peaks are gone (also I can see the light getting transmitted out of the cavity by naked eye, using an IR viewer card, and I wouldn't be able to, unless I have some power amplification).

However, as you can see in the figure, the height of the peaks varies a lot. Also if I zoom into only one of the peaks, it doesn't have a nice Lorentzian shape. Instead, it has multiple, smaller and spread peaks inside of it (I can take a picture of that, too, if needed). I would think that vibrations might play a role, as I am currently not floating the table I am using, but it is still an optical table still, with good damping, so I wouldn't expect vibrations to play such a big role (but I am not sure).

It is the first time I am aligning a cavity, so I would really appreciate any insight into this (or ways in which I can debug this issue). Please let me know if you need further details about the setup. Thank you!

The cavity has a linewidth of 25 kHz and the laser has a linewidth of 5 kHz (at 1064 nm and 20 W power). Currently I am trying to align the cavity and I am scanning the laser frequency while adjusting the mirrors. I am able to see (by measuring with a diode the transmission from one of the mirrors) the cavity modes (see attached figure), but they look kinda weird. I am pretty sure these are due to amplification inside the cavity, as if I block one of the paths inside the cavity all the peaks are gone (also I can see the light getting transmitted out of the cavity by naked eye, using an IR viewer card, and I wouldn't be able to, unless I have some power amplification).

However, as you can see in the figure, the height of the peaks varies a lot. Also if I zoom into only one of the peaks, it doesn't have a nice Lorentzian shape. Instead, it has multiple, smaller and spread peaks inside of it (I can take a picture of that, too, if needed). I would think that vibrations might play a role, as I am currently not floating the table I am using, but it is still an optical table still, with good damping, so I wouldn't expect vibrations to play such a big role (but I am not sure).

It is the first time I am aligning a cavity, so I would really appreciate any insight into this (or ways in which I can debug this issue). Please let me know if you need further details about the setup. Thank you!

Last edited by a moderator: