- #1

Amaelle

- 310

- 54

- TL;DR Summary

- Good day!

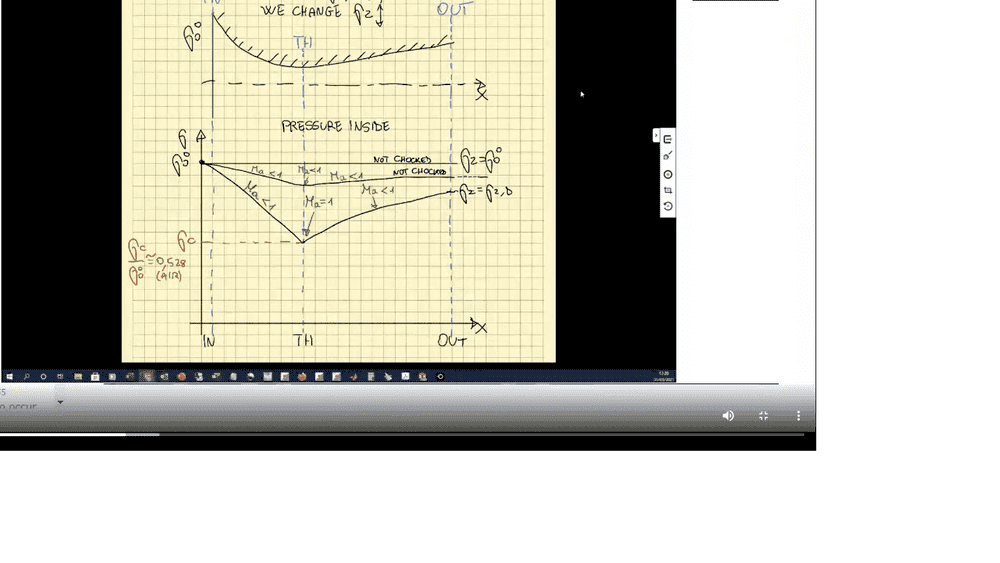

I have a question regarding the converging-diverging nozzle (look at the image)

Normally, in order to expand the mass flow rate, we reduce the downstream pressure

my question is how can we reach the sonic condition in the throat when the downstream pressure is considerably high(does not reach the critical pressure?

many thanks in advance

Good day!

I have a question regarding the converging-diverging nozzle (look at the image)

Normally, in order to expand the mass flow rate, we reduce the downstream pressure

my question is how can we reach the sonic condition in the throat when the downstream pressure is considerably high(does not reach the critical pressure?

many thanks in advance

I have a question regarding the converging-diverging nozzle (look at the image)

Normally, in order to expand the mass flow rate, we reduce the downstream pressure

my question is how can we reach the sonic condition in the throat when the downstream pressure is considerably high(does not reach the critical pressure?

many thanks in advance

Last edited by a moderator: