- #1

patehi

- 11

- 0

Hi all,

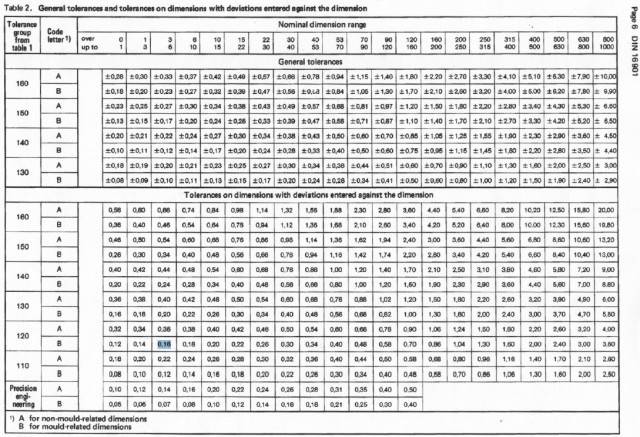

i have stumbled across a drawing which referenced DIN 16901 for its tolerance. I have a table of DIN 16091 which i don't understand.

For the first half of the tables, the tolerances are + and -, which i understand. The second half (tolerances on dimensions with Deviations entered against the dimensions) are without +/- symbols. Can i assume that the tolerances are always + ?

Thanks guys for your help!

i have stumbled across a drawing which referenced DIN 16901 for its tolerance. I have a table of DIN 16091 which i don't understand.

For the first half of the tables, the tolerances are + and -, which i understand. The second half (tolerances on dimensions with Deviations entered against the dimensions) are without +/- symbols. Can i assume that the tolerances are always + ?

Thanks guys for your help!