BigNick

- 5

- 2

Dear all,

First of all I would like to thank everyone for this great forum. I've been reading the forum for years, but I hadn't registered until today.

My registration on this forum obviously has a reason. I have an issue that I can't quite figure out.

I am trying to calculate how much power I need to cool and dehumidify a room in combination with reheating the air for comfort.

The thermodynamic calculations seem to be correct. However, I'm not sure about the time factor.

My doubts are caused by the fact that there are several ventilations per hour and therefore also varying needed power.

The goal of the calculation is to pass on the required kW for the configuration of the cooling coil and heat coil to the supplier, who makes the coils.

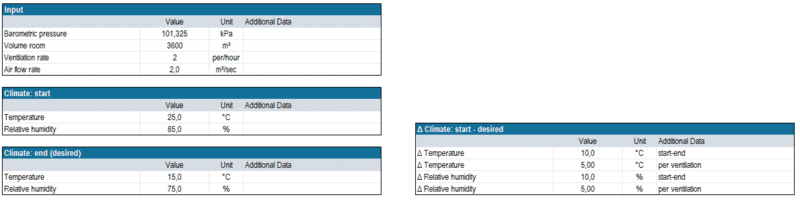

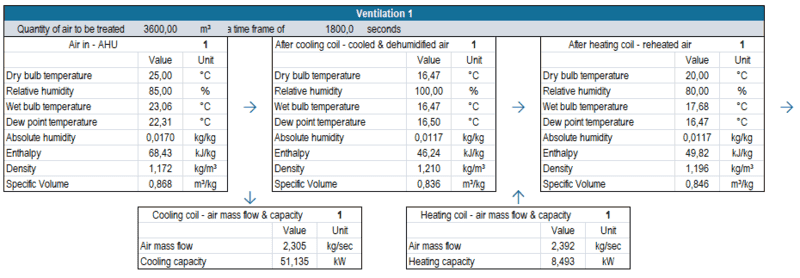

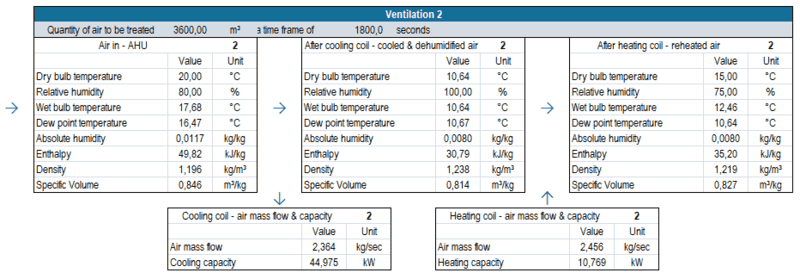

The input data and the progress of the process in the attached images. For simplicity I have omitted all external factors (such as heat loss and, for example, moisture / heat production by people). In addition, it is important to mention that it is a recirculation process. No air is supplied/mixed from outside.

My question is, what number of kW is correct and should I provide to the coil supplier?

Cooling coil:

A: (Q1coolcoil / 2) + (Q2coolcoil / 2) - the division by 2 because each ventilation takes 1800 seconds.

A: (51,135 kW / 2) + (44,975 kW / 2) = 48,055 kW

B: 51,135 kW

C: 44,975 kW

Heating coil:

A: (Q1heatcoil / 2) + (Q2heatcoil / 2) - the division by 2 because each ventilation takes 1800 seconds.

A: (8,493 kW / 2) + (10,769 kW / 2) = 9,631 kW

B: 8,493 kW

C: 10,769 kW

My gut tells me that Im converting answer A to kWh. But I'm not quite sure. Or is this right and is kW expressed in a time frame of 1 hour?

Who can explain to me what mistake I'm making?

Many thanks in advance,

First of all I would like to thank everyone for this great forum. I've been reading the forum for years, but I hadn't registered until today.

My registration on this forum obviously has a reason. I have an issue that I can't quite figure out.

I am trying to calculate how much power I need to cool and dehumidify a room in combination with reheating the air for comfort.

The thermodynamic calculations seem to be correct. However, I'm not sure about the time factor.

My doubts are caused by the fact that there are several ventilations per hour and therefore also varying needed power.

The goal of the calculation is to pass on the required kW for the configuration of the cooling coil and heat coil to the supplier, who makes the coils.

The input data and the progress of the process in the attached images. For simplicity I have omitted all external factors (such as heat loss and, for example, moisture / heat production by people). In addition, it is important to mention that it is a recirculation process. No air is supplied/mixed from outside.

My question is, what number of kW is correct and should I provide to the coil supplier?

Cooling coil:

A: (Q1coolcoil / 2) + (Q2coolcoil / 2) - the division by 2 because each ventilation takes 1800 seconds.

A: (51,135 kW / 2) + (44,975 kW / 2) = 48,055 kW

B: 51,135 kW

C: 44,975 kW

Heating coil:

A: (Q1heatcoil / 2) + (Q2heatcoil / 2) - the division by 2 because each ventilation takes 1800 seconds.

A: (8,493 kW / 2) + (10,769 kW / 2) = 9,631 kW

B: 8,493 kW

C: 10,769 kW

My gut tells me that Im converting answer A to kWh. But I'm not quite sure. Or is this right and is kW expressed in a time frame of 1 hour?

Who can explain to me what mistake I'm making?

Many thanks in advance,