MrHappyTree

- 4

- 2

- TL;DR Summary

- The influence of the geometry on the electrical resistance of a component.

For the electrical resistance ##R## of an ideal wire, we all know the formula ##R=\rho * \frac{l}{A}##. However this is only valid for a cylinder with constant cross sectional area ##A##.

In a cone the cross section area is reduced over its height (or length ##l##). What is a good general approach for the calculation of resistance of such defined but more complex geometries?

Example:

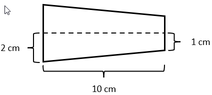

A straight cone has a base radius of 0.02 m and a cut tip with radius of 0.01 m in a height of 0.1 m (sketch). Copper has a resistivity ##\rho## of 17 nΩ⋅m.

First approach: The resistance over the length of the cone sections is between the calculations for a constant radius with 0.01 and 0.02 therefore 5.4 mΩ > R > 1.4 mΩ. Is it possible to add the resistance of infinitely small wire sections together to approximate the shape?

Thank you for your ideas

In a cone the cross section area is reduced over its height (or length ##l##). What is a good general approach for the calculation of resistance of such defined but more complex geometries?

Example:

A straight cone has a base radius of 0.02 m and a cut tip with radius of 0.01 m in a height of 0.1 m (sketch). Copper has a resistivity ##\rho## of 17 nΩ⋅m.

First approach: The resistance over the length of the cone sections is between the calculations for a constant radius with 0.01 and 0.02 therefore 5.4 mΩ > R > 1.4 mΩ. Is it possible to add the resistance of infinitely small wire sections together to approximate the shape?

Thank you for your ideas

Attachments

Last edited: