- #1

jamesson

- 59

- 3

Howdy folks

I have to say up-front, that I am not an ME by trade. My background is in EE. So, I apologize in advance if I accidentally make my question confusing.

I need to join a couple of these

http://www.minitecframing.com/Produ...talog_Pages/20.1074_19X11_Profile_Square.html

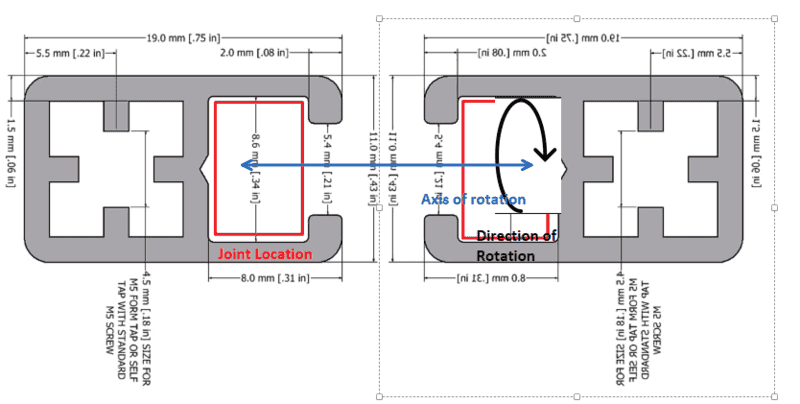

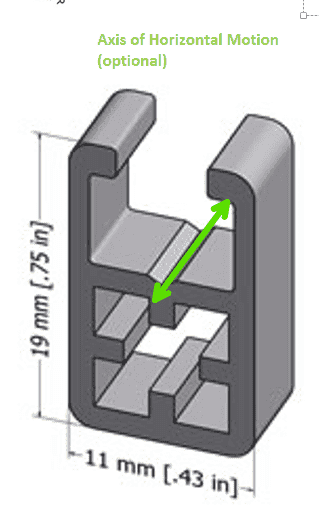

with a bearing that will allow rotation along one axis. I need to provide a bearing that will go in the outer slot (red rectangle) and provide rotation around the central axis (blue line)

Could be a bearing, could be a simple "pin" of Teflon or some other low-friction material. I would like the option of either fixing linear motion in the slot or letting it move freely,

but if only one of those options is possible, I will go with whatever is cheapest. As you can see from the site, they have their own nuts and bolts for fixed joints, so if my only (reasonably priced) option is to have something sitting outside the slot, so be it.

The primary design parameter is price, followed closely by durability. I expect it to be used 5-10 times a day for a period of some years, and experience lateral stress (perpendicular to axis of rotation) of approximately 20-40 lbs. Also, if it's any more than $1/piece, I may have to rethink the project.

In general, I am extremely curious about the process you folks use to find stuff like this. I'm assuming people don't just send drawings to McMaster-Carr?

Many thanks in advance for any help

Joe

I have to say up-front, that I am not an ME by trade. My background is in EE. So, I apologize in advance if I accidentally make my question confusing.

I need to join a couple of these

http://www.minitecframing.com/Produ...talog_Pages/20.1074_19X11_Profile_Square.html

with a bearing that will allow rotation along one axis. I need to provide a bearing that will go in the outer slot (red rectangle) and provide rotation around the central axis (blue line)

Could be a bearing, could be a simple "pin" of Teflon or some other low-friction material. I would like the option of either fixing linear motion in the slot or letting it move freely,

but if only one of those options is possible, I will go with whatever is cheapest. As you can see from the site, they have their own nuts and bolts for fixed joints, so if my only (reasonably priced) option is to have something sitting outside the slot, so be it.

The primary design parameter is price, followed closely by durability. I expect it to be used 5-10 times a day for a period of some years, and experience lateral stress (perpendicular to axis of rotation) of approximately 20-40 lbs. Also, if it's any more than $1/piece, I may have to rethink the project.

In general, I am extremely curious about the process you folks use to find stuff like this. I'm assuming people don't just send drawings to McMaster-Carr?

Many thanks in advance for any help

Joe