kazx9r

- 49

- 4

Hello all, i posted this on another forum but didn't get much response, I had an 18” centrifugal fan around around and wanted to see if I can push some real air to make a wind tunnel. I'm just a hobbyist, and like to build and modify cars, figured this would be something to look into.

Looks like this:

Trust me this thing is heavy and pretty big but is it big enough?

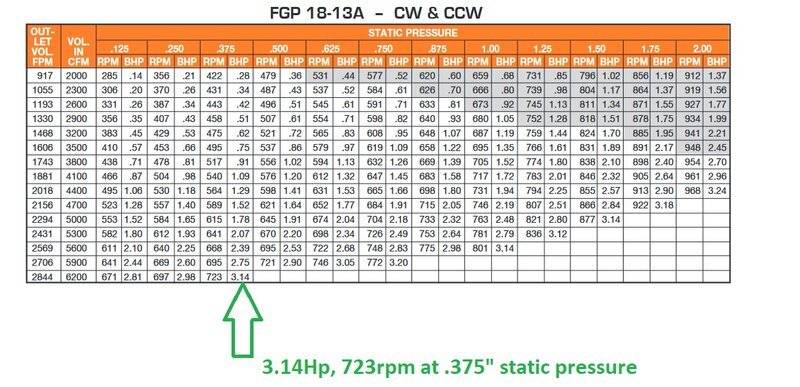

Spec picture Shown here page 107

18-13a, so 18 diameter with about a 18”x18” outlet.

18-13a, so 18 diameter with about a 18”x18” outlet.

Chart only goes to 723rpm but I got this up to just above 2000rpm, took 14Hp, I may add some more motors.

Excuse the mess just a test run for 2 minutes just a 12 second clip:

Crazy right? This thing really blows some air, my guess 50-70mph (need a wind meter) my plan is to test small winglets for downforce.

My question is the honeycomb, is it needed? Amazon has a few but they're 1/4" holes but only 1", i need probably around 3-6" for a honeycomb? any thoughts.

I would greatly appreciate if someone could share their experiences or critique this project.

Looks like this:

Trust me this thing is heavy and pretty big but is it big enough?

Spec picture Shown here page 107

Chart only goes to 723rpm but I got this up to just above 2000rpm, took 14Hp, I may add some more motors.

Excuse the mess just a test run for 2 minutes just a 12 second clip:

Crazy right? This thing really blows some air, my guess 50-70mph (need a wind meter) my plan is to test small winglets for downforce.

My question is the honeycomb, is it needed? Amazon has a few but they're 1/4" holes but only 1", i need probably around 3-6" for a honeycomb? any thoughts.

I would greatly appreciate if someone could share their experiences or critique this project.