- #1

beamthegreat

- 116

- 7

Hi all. I have a rather unique problem that I need help with and I really didn't know how to title it.

Consider the following:

You are trying to build a factory that produces the greatest amount of goods under a given time.

You start off with a construction capacity of 20 per hour and you can choose to construct any of the following structures below in any order.

Structure A: produces 2 goods per hour - Initial cost 5

Structure B: produces 1 goods per hour AND increases the construction capacity by 3 - Initial cost 1

Structure C: produces 1 goods per hour AND increases the construction capacity by 2 - Initial cost 5

There are 2 rules:

1. Each consecutive structure you build increases the cost of the next structure by 1.5x.

2. The amount of goods you produce is calculated precisely at the end of each hour.

______________________________________________

For example, if you choose to construct "A", it will take you 15 minutes (5/20 hours) to complete the first structure. And if you choose to construct an additional "A", it will take you another 22 minutes 30 seconds (5*1.5/20), then 33 minutes 45 seconds (5*1.52/20) etc, etc.

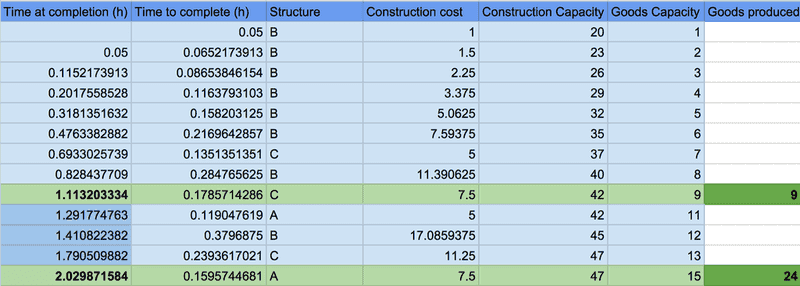

However, if you choose to construct "B", it will take you 1/20 = 3 minutes to complete the first structure. The next "B" structure would take 3 minute 54.78 seconds (1*1.5 / 20+3), then 5 minutes 11.54 seconds (1*1.52 / 20+[3*2]) etc, etc.As mentioned before, you can alternate between structures so you can switch between any structures freely.Here is a chart of a simulation (probably not optimal) you can take a look to get an idea of how it works:

As you can see, building the structures in the following order: B,B,B,B,B,B,C,B,C,A,B,C,A yields a total of 24 goods within 2 hours.

My question is, what is the optimal order to build structures for, 10 hours, 20 hours and 50 hours in order to maximize the amount of goods?

How does one even attempt to solve this problem?

Thanks!

Consider the following:

You are trying to build a factory that produces the greatest amount of goods under a given time.

You start off with a construction capacity of 20 per hour and you can choose to construct any of the following structures below in any order.

Structure A: produces 2 goods per hour - Initial cost 5

Structure B: produces 1 goods per hour AND increases the construction capacity by 3 - Initial cost 1

Structure C: produces 1 goods per hour AND increases the construction capacity by 2 - Initial cost 5

There are 2 rules:

1. Each consecutive structure you build increases the cost of the next structure by 1.5x.

2. The amount of goods you produce is calculated precisely at the end of each hour.

______________________________________________

For example, if you choose to construct "A", it will take you 15 minutes (5/20 hours) to complete the first structure. And if you choose to construct an additional "A", it will take you another 22 minutes 30 seconds (5*1.5/20), then 33 minutes 45 seconds (5*1.52/20) etc, etc.

However, if you choose to construct "B", it will take you 1/20 = 3 minutes to complete the first structure. The next "B" structure would take 3 minute 54.78 seconds (1*1.5 / 20+3), then 5 minutes 11.54 seconds (1*1.52 / 20+[3*2]) etc, etc.As mentioned before, you can alternate between structures so you can switch between any structures freely.Here is a chart of a simulation (probably not optimal) you can take a look to get an idea of how it works:

As you can see, building the structures in the following order: B,B,B,B,B,B,C,B,C,A,B,C,A yields a total of 24 goods within 2 hours.

My question is, what is the optimal order to build structures for, 10 hours, 20 hours and 50 hours in order to maximize the amount of goods?

How does one even attempt to solve this problem?

Thanks!

Last edited: