- #1

Dafe

- 145

- 0

Hey, I'm trying to learn a bit about the strength of threads in bolts and have a couple of questions.

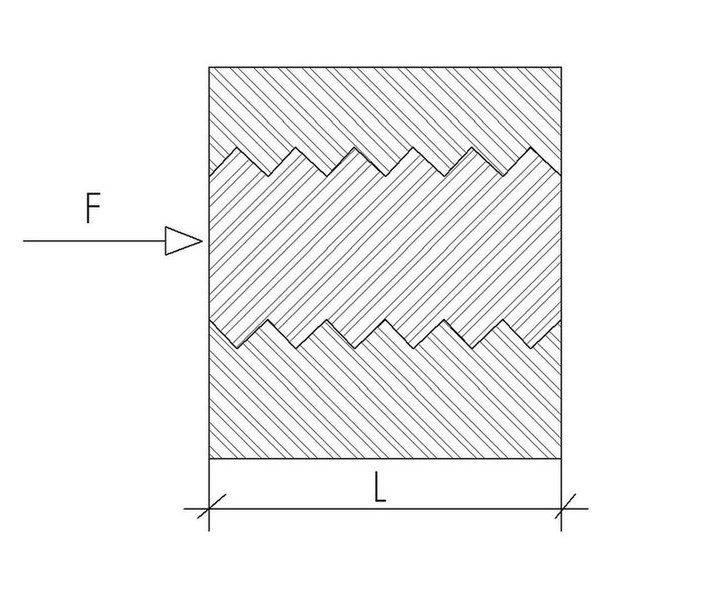

Let's say I have a system that looks something like this:

I want to find out if there are enough threads to withstand the force F.

The nut and bolt material are not the same.

I have done some research and found out that ANSI has a couple of equations for this type of analysis.

First we have the Shear Area of External Threads :

A_s,e = pi*n*L_e*K_nmax*[1/2n + 1/sqrt3*(E_s,min-K_nmax)]

where

n=threads/inch

L_e=Length of engagement

K_nmax=maximum inner diameter of nut

E_s,min=minimum pitch diameter of bolt

I really don't understand this equation. This is supposed to be the area where shear will occur right? How is it that they use the length of engagement to get that area?

Can I divide the force F with this area and compare the results with the shear strength of the material?

I know, a lot of questions, hope someone can give me some hints.

Thank you

Let's say I have a system that looks something like this:

I want to find out if there are enough threads to withstand the force F.

The nut and bolt material are not the same.

I have done some research and found out that ANSI has a couple of equations for this type of analysis.

First we have the Shear Area of External Threads :

A_s,e = pi*n*L_e*K_nmax*[1/2n + 1/sqrt3*(E_s,min-K_nmax)]

where

n=threads/inch

L_e=Length of engagement

K_nmax=maximum inner diameter of nut

E_s,min=minimum pitch diameter of bolt

I really don't understand this equation. This is supposed to be the area where shear will occur right? How is it that they use the length of engagement to get that area?

Can I divide the force F with this area and compare the results with the shear strength of the material?

I know, a lot of questions, hope someone can give me some hints.

Thank you