Runeforged

- 1

- 0

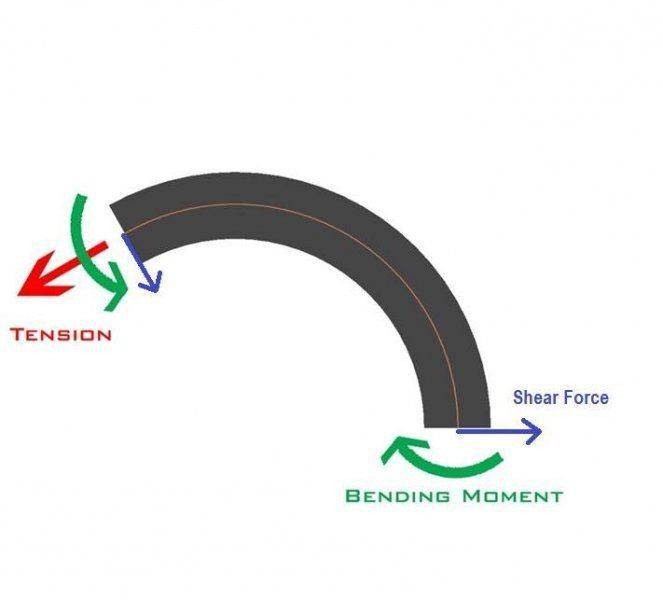

I am a student currently working on a group project regarding the design of a gooseneck for a sub-sea pipeline. For those not familiar, a gooseneck is essentially a 45 degree bent pipe, to be used as a connection between a manifold and a longer pipeline (a flexible riser). part of this design is a stress analysis to prove its strength. This has proven to be much harder than anticipated, so i would like to ask for some pointers.

We already know our bending moment, tension and shear.

So far we've been able to calculate for burst pressure,longitudinal and combined longitudinal loads, collapse pressure (all from the API standard 1111), and bending stress. We have however not been able to calculate for shear stresses (would calculating the hoop stress be sufficient for this?) and axial stresses, how would we go about this? Any other calculation you feel need to be added for a more complete stress analysis? Any feedback is welcome as we are very much amateurs when it comes to mechanical engineering.

Below is a force diagram of how we've understood the forces acting on the pipe.

We already know our bending moment, tension and shear.

So far we've been able to calculate for burst pressure,longitudinal and combined longitudinal loads, collapse pressure (all from the API standard 1111), and bending stress. We have however not been able to calculate for shear stresses (would calculating the hoop stress be sufficient for this?) and axial stresses, how would we go about this? Any other calculation you feel need to be added for a more complete stress analysis? Any feedback is welcome as we are very much amateurs when it comes to mechanical engineering.

Below is a force diagram of how we've understood the forces acting on the pipe.

Last edited: