- #1

CMW328i

- 8

- 1

Thread moved from the technical forums to HH, so no HH Template is shown

Hi all, first post here.

I'm currently faced with an assignment in a class where we really haven't been taught anything and have to figure it out on our own. We've been asked to design an industrial lift system to raise approximately 3000 kg up 25 stories. I have done a lot of research and have been able to design a suitable platform frame with less than 3mm of deflection at maximum loading. I've also been able to calculate the required torque and kW rating of the motors I want to use. However, I am left with a few problems left to figure out and I'm not sure where to begin looking for solutions.

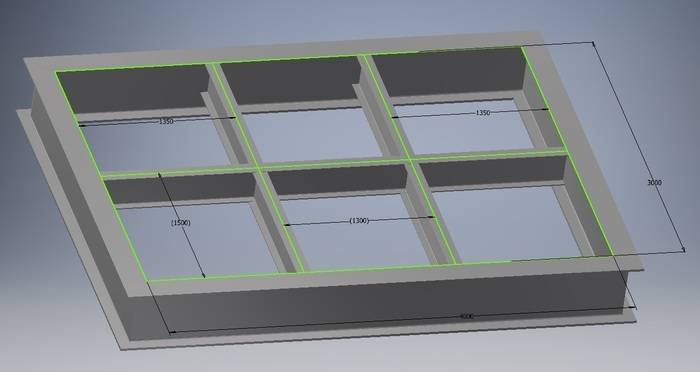

My frame is made from standard UK beam segments in a simple criss-cross pattern as below:

The assignment says:

"The floor needed to be constructed from the suitable expanded metal as per the given cage dimensions. The construction company would like the floor to be made of suitable light metal to keep the Material Cost to the minimum."

now, I could just slap a 200 mm steel plate across the frame and I'm sure that would be sufficient, but I honestly have NO idea how to begin to select a suitable material and thickness for this application. The most relevant teaching I've had was 2 years ago doing simply supported beam bending analysis, but this strikes me as a more complex type of calculation. Considering that it is a lift, I imagine that it should be able to take a "point load" of the maximum rated load of 3000 kg. This seems like the sort of thing a lightweight aluminium sheet might not be happy with. Can anyone suggest a way to calculate this?

also, the assignment gives us this:

"Power Supply Range : 370- 460 V,50 or 60 Hz,3 Phase

Rated power: kW ?

Power supply Fuse ?

Starting Current : 130 A

Power Consumption :65 kVA"

I've calculated that I would need about 17 kW with safety margin to lift this load with my design. I've never been asked to decide what fuse to use. Any pointers on that would be appreciated as well :)

Thanks in advance for any help you can offer!

-Chris

I'm currently faced with an assignment in a class where we really haven't been taught anything and have to figure it out on our own. We've been asked to design an industrial lift system to raise approximately 3000 kg up 25 stories. I have done a lot of research and have been able to design a suitable platform frame with less than 3mm of deflection at maximum loading. I've also been able to calculate the required torque and kW rating of the motors I want to use. However, I am left with a few problems left to figure out and I'm not sure where to begin looking for solutions.

My frame is made from standard UK beam segments in a simple criss-cross pattern as below:

The assignment says:

"The floor needed to be constructed from the suitable expanded metal as per the given cage dimensions. The construction company would like the floor to be made of suitable light metal to keep the Material Cost to the minimum."

now, I could just slap a 200 mm steel plate across the frame and I'm sure that would be sufficient, but I honestly have NO idea how to begin to select a suitable material and thickness for this application. The most relevant teaching I've had was 2 years ago doing simply supported beam bending analysis, but this strikes me as a more complex type of calculation. Considering that it is a lift, I imagine that it should be able to take a "point load" of the maximum rated load of 3000 kg. This seems like the sort of thing a lightweight aluminium sheet might not be happy with. Can anyone suggest a way to calculate this?

also, the assignment gives us this:

"Power Supply Range : 370- 460 V,50 or 60 Hz,3 Phase

Rated power: kW ?

Power supply Fuse ?

Starting Current : 130 A

Power Consumption :65 kVA"

I've calculated that I would need about 17 kW with safety margin to lift this load with my design. I've never been asked to decide what fuse to use. Any pointers on that would be appreciated as well :)

Thanks in advance for any help you can offer!

-Chris