- #1

Sefi

- 4

- 3

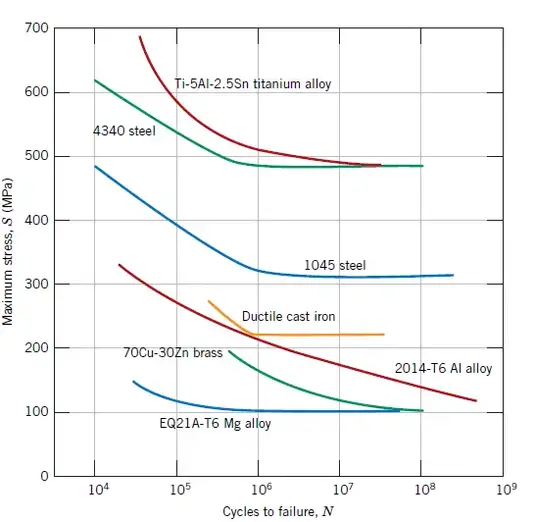

Hello, assuming to keep an aluminum alloy motorcycle frame not in use, still, will the daily temperature variations cause thermal fatigue due to the continuous expansions and retractions or is the force developed by a few degrees of variations not sufficient to create microstructural dislocations?