Mech_LS24

- 148

- 16

- Homework Statement

- Friction applied on screws (power screw)

- Relevant Equations

- M=r∙W∙tan(∅s+θ)

θ=tan^(-1)(l∕2πr)

∅s=tan^(-1)〖(F∕N) = tan^(-1)μs 〗

Hello all,

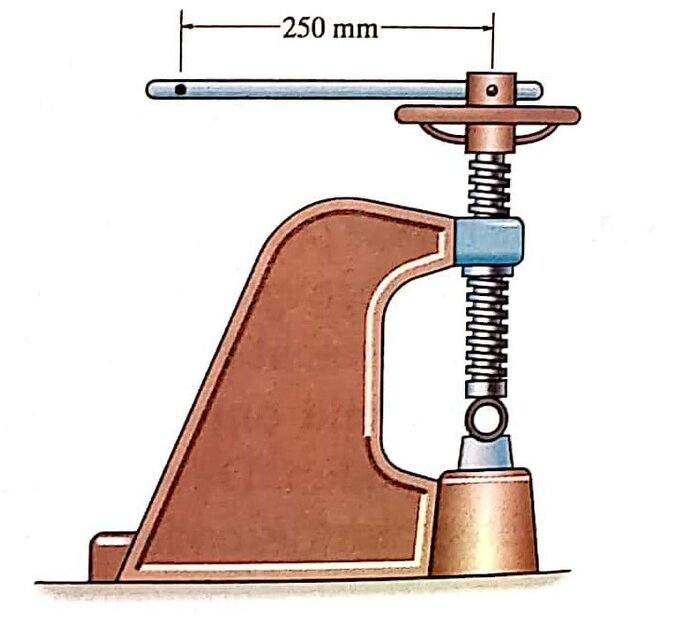

I need some help with a problem at statics, friction applied on threads. A threaded screw is given a ("horizontal") force of 100 N at the end of the handle. As the exercise states, they ask to calculate the force which occurs at the tube as well as the force needed to vise handle to release is.

With the formulas:

M=r∙W∙tan(∅s+θ)

θ=tan^(-1)(l∕2πr)

∅s=tan^(-1)〖(F∕N) = tan^(-1)μs 〗

First I calculated the Torque (which is M in the formula), M = 100 N * 250 = 25000 Nmm. The angles are found by using the mean diameter and friction coefficient of 0.3.

I founded the force W of 3.84 kN which is correct. But for the second question, the books gives a solution of 73.3 kN of force is needed to release the vise handle and I can't figure out how to solve this.

Hopefully someone can help.

Thanks in advance!

I need some help with a problem at statics, friction applied on threads. A threaded screw is given a ("horizontal") force of 100 N at the end of the handle. As the exercise states, they ask to calculate the force which occurs at the tube as well as the force needed to vise handle to release is.

With the formulas:

M=r∙W∙tan(∅s+θ)

θ=tan^(-1)(l∕2πr)

∅s=tan^(-1)〖(F∕N) = tan^(-1)μs 〗

First I calculated the Torque (which is M in the formula), M = 100 N * 250 = 25000 Nmm. The angles are found by using the mean diameter and friction coefficient of 0.3.

I founded the force W of 3.84 kN which is correct. But for the second question, the books gives a solution of 73.3 kN of force is needed to release the vise handle and I can't figure out how to solve this.

Hopefully someone can help.

Thanks in advance!