- #1

rohmand

- 5

- 0

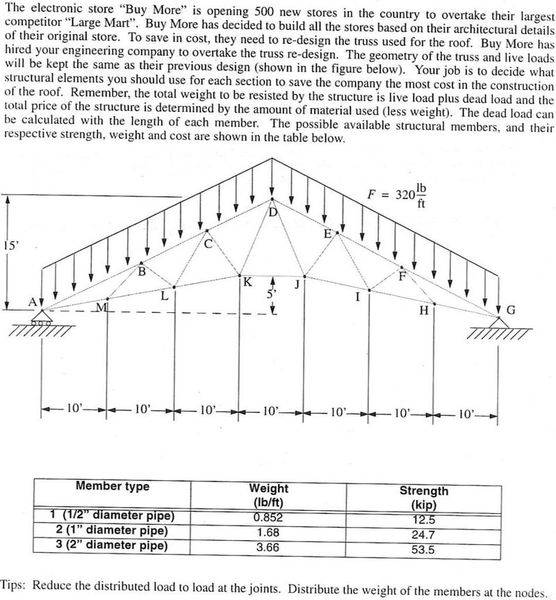

We were given a small project to do before a test in my engineering statics class, i understand the goals of the project and understand the steps i need to take (i believe) however i don't understand how to simplify the distributed load into something i can anylize as we haven't seen anything like this in class and there's nothing in the book even comparible to it.

I understand obviously i need to break this down and see what kind of tension and compression i am putting on the truss members so that i can decide which types of tubes i need to design this truss with, what i don't understand is how do i turn this distributed load across the roof into a load i can understand as being put on each node, do i just find the Fr by using the integral and say i have a point load in the center of this truss of whatever that ends up being and if so would i say the per foot is per foot of x-axis or per foot along the roof line (hypotenuse)? the more i look at this thing the more i see more questions that i don't know the answer to or have multiple answers. i really want to understand this as it will help with being prepared for my test and i need to get this thing done so i can study for the rest of the material on my test. please any help pointing me in the right direction would be greatly appreciated. i searched for other posts similar to this but didnt find anything i could relate exactly which may be because i am missing a major step here, i did find this exact problem and actually used his link for the photo which hopefully works but nobody posted on his as well and i see that he came up with some point loads but rather than just use his info i would like to know if and why he is right?

I understand obviously i need to break this down and see what kind of tension and compression i am putting on the truss members so that i can decide which types of tubes i need to design this truss with, what i don't understand is how do i turn this distributed load across the roof into a load i can understand as being put on each node, do i just find the Fr by using the integral and say i have a point load in the center of this truss of whatever that ends up being and if so would i say the per foot is per foot of x-axis or per foot along the roof line (hypotenuse)? the more i look at this thing the more i see more questions that i don't know the answer to or have multiple answers. i really want to understand this as it will help with being prepared for my test and i need to get this thing done so i can study for the rest of the material on my test. please any help pointing me in the right direction would be greatly appreciated. i searched for other posts similar to this but didnt find anything i could relate exactly which may be because i am missing a major step here, i did find this exact problem and actually used his link for the photo which hopefully works but nobody posted on his as well and i see that he came up with some point loads but rather than just use his info i would like to know if and why he is right?