- #1

MexChemE

- 237

- 55

Hello, PF! I've been learning some process control on my own lately, and some questions have come to my head while on it.

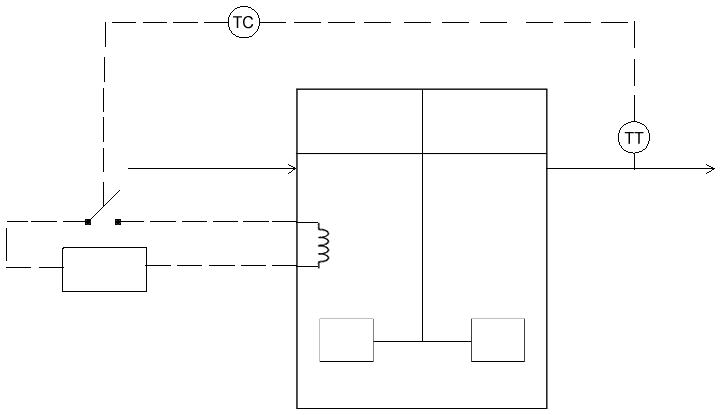

Consider the following on-off control loop:

Let's say we want to control the temperature of the fluid inside the tank. We set up an on-off control loop and establish a temperature set point [itex]T_{sp}[/itex], then we measure the outlet temperature of the fluid [itex]T[/itex]. As long as [itex]T < T_{sp}[/itex], the controller activates a constant-power electrical heater, and it turns it off once [itex]T < T_{sp}[/itex]. Now, I know this is a very rudimentary description, but I think it gets the job done. Let's say the controller is a PLC, so we set up our ladder logic program with an open contact for the temperature sensor input that gets energized as long as [itex]T < T_{sp}[/itex], and the corresponding output coil for the electrical heater. Clearly, this system can run on digital signals only.

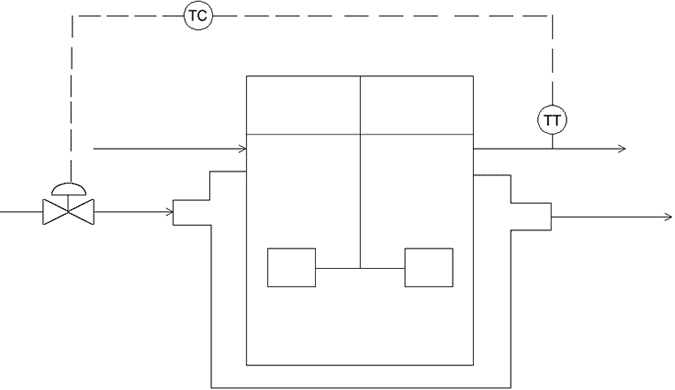

Now, consider the following PID control loop:

Now we have a steam heating jacket, and we can control its mass flowrate using a control valve. Now we need an analog temperature sensor which provides a continuous reading of the outlet temperature. Let's say we're still running the control loop on a PLC, so we need analog I/O modules in order to receive the analog signals from the sensor, and send the output signals to the valve actuator, which should adjust mass flowrate accordingly. Now, this system runs mostly on analog signals, at least the instrumentation has to.

Now, my questions are:

1. Do on-off control loops mostly run on digital signals? As a process control newbie, I don't see the need for an on-off loop using analog instrumentation.

2. Do PID loops always imply analog instrumentation? Could a PID loop run on just digital hardware?

3. PID loops seem to be ubiquitous in the chemical processes industry, are on-off loops used at all as an alternative to PID control? Not when accuracy is critical, I think.

P.S. I'm currently taking a practical course on PLC programming by a local engineering firm, and it's really nice because we always end up assembling the actual machines to run our programs, and we mostly do everything from scratch, from the programming to the actual wiring of sensors and actuators. As a chemical engineering major, I'm learning a lot about electrics/electronics and pneumatics, which are useful skills to have, however, we mostly program for discrete processes, such as assembly lines, which are not that relevant to my major.

Thanks in advance for any input!

Consider the following on-off control loop:

Let's say we want to control the temperature of the fluid inside the tank. We set up an on-off control loop and establish a temperature set point [itex]T_{sp}[/itex], then we measure the outlet temperature of the fluid [itex]T[/itex]. As long as [itex]T < T_{sp}[/itex], the controller activates a constant-power electrical heater, and it turns it off once [itex]T < T_{sp}[/itex]. Now, I know this is a very rudimentary description, but I think it gets the job done. Let's say the controller is a PLC, so we set up our ladder logic program with an open contact for the temperature sensor input that gets energized as long as [itex]T < T_{sp}[/itex], and the corresponding output coil for the electrical heater. Clearly, this system can run on digital signals only.

Now, consider the following PID control loop:

Now we have a steam heating jacket, and we can control its mass flowrate using a control valve. Now we need an analog temperature sensor which provides a continuous reading of the outlet temperature. Let's say we're still running the control loop on a PLC, so we need analog I/O modules in order to receive the analog signals from the sensor, and send the output signals to the valve actuator, which should adjust mass flowrate accordingly. Now, this system runs mostly on analog signals, at least the instrumentation has to.

Now, my questions are:

1. Do on-off control loops mostly run on digital signals? As a process control newbie, I don't see the need for an on-off loop using analog instrumentation.

2. Do PID loops always imply analog instrumentation? Could a PID loop run on just digital hardware?

3. PID loops seem to be ubiquitous in the chemical processes industry, are on-off loops used at all as an alternative to PID control? Not when accuracy is critical, I think.

P.S. I'm currently taking a practical course on PLC programming by a local engineering firm, and it's really nice because we always end up assembling the actual machines to run our programs, and we mostly do everything from scratch, from the programming to the actual wiring of sensors and actuators. As a chemical engineering major, I'm learning a lot about electrics/electronics and pneumatics, which are useful skills to have, however, we mostly program for discrete processes, such as assembly lines, which are not that relevant to my major.

Thanks in advance for any input!