- #1

Leo Liu

- 353

- 156

I have just watched a video lecture about the Tomlinson model (aka Prandtl–Tomlinson Model) which explains the friction mechanism at a nanoscale by analogy with a tip dragged by a spring. The video has prompted me to ask several questions.

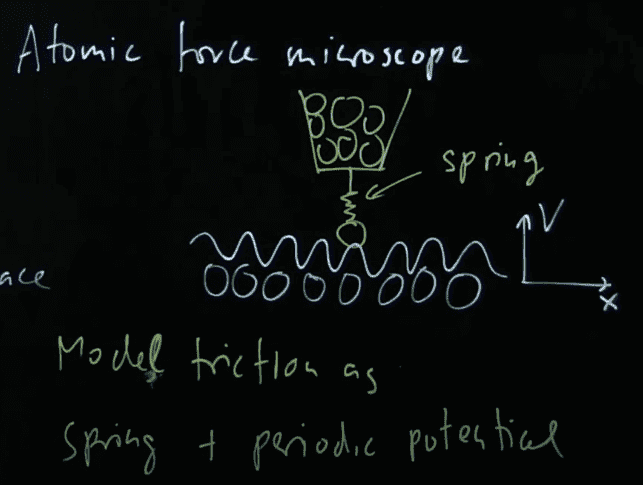

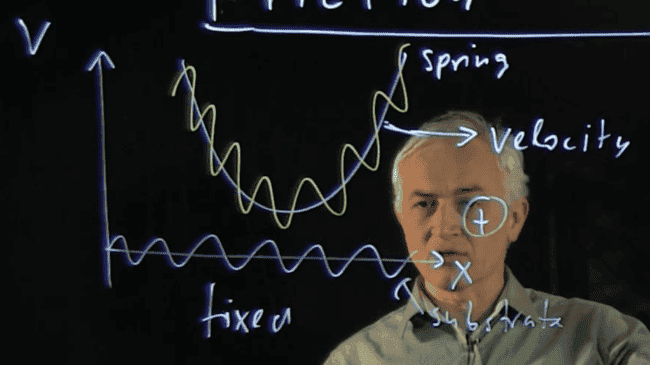

The spring is dragged over a corrugated substrate, as shown in the picture above. Because of the corrugation, the potential energy curve of the substrate is periodic.

However, I am not quite sure why there is some potential energy between the nanotip and the substrate-- my guess is that the potential energy is stored within the intermolecular forces between the tip and the molecules in the substrate. Could someone provide an explanation?

Then he mentions that the curve of the potential energy of the spring is quadratic. Because the length of the spring is constantly changing, I wonder why the EP curve of the spring does not show any periodicity.

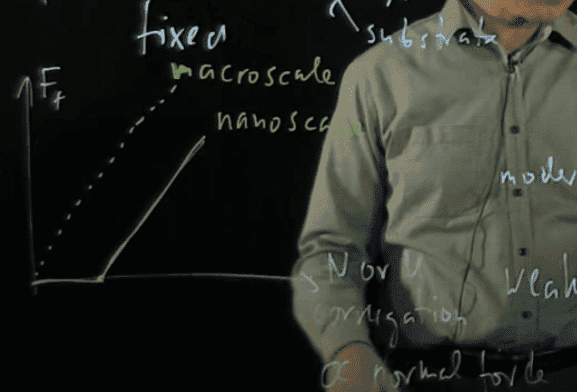

Last, why is the corrugation of the potential energy proportional to the normal force?

I would also like to invite you to share your knowledge and insight into this model or the mechanism of friction on the atomic scale. Thank you.

The spring is dragged over a corrugated substrate, as shown in the picture above. Because of the corrugation, the potential energy curve of the substrate is periodic.

However, I am not quite sure why there is some potential energy between the nanotip and the substrate-- my guess is that the potential energy is stored within the intermolecular forces between the tip and the molecules in the substrate. Could someone provide an explanation?

Then he mentions that the curve of the potential energy of the spring is quadratic. Because the length of the spring is constantly changing, I wonder why the EP curve of the spring does not show any periodicity.

Last, why is the corrugation of the potential energy proportional to the normal force?

I would also like to invite you to share your knowledge and insight into this model or the mechanism of friction on the atomic scale. Thank you.

Last edited: