- #1

FAlonso

- 112

- 4

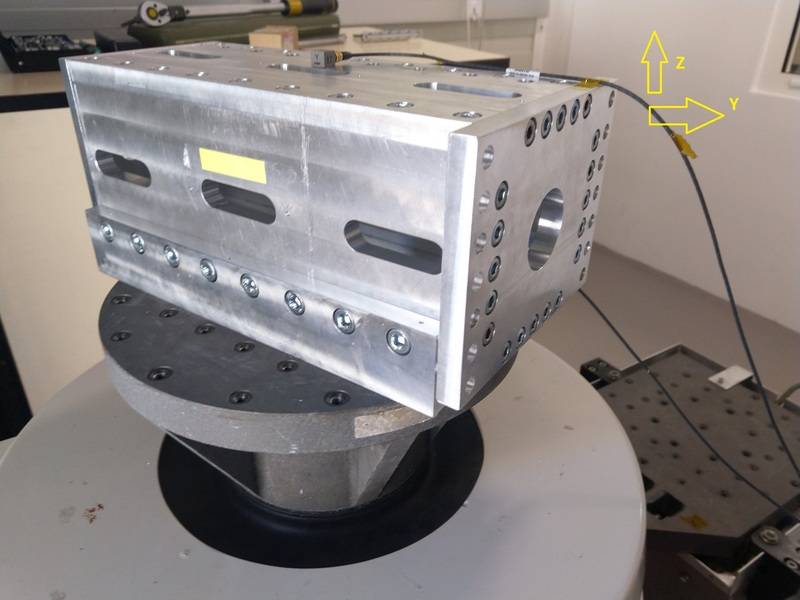

Hello everyone, I wanted to gather opinion from anyone experienced in vibration regarding one of test fixtures I have created for small satellites. The image below shows the Test-POD that I am testing on a single axis shaker. In one of the tests, I had troubles that the amplitude got higher than limits (3g) in Y-direction. This is not the direction in which force is being applied. I did it three times and had abort at all three moments at around 1860 Hz (My test range is 0 - 2000 Hz).

Why is it that I am observing a very high amplitude (more than 3g) in Y-direction and not in the Z-direction (which is the direction force is being applied)? I apply 0.4g at the base in vertical direction. Of course there are resonances in the test range, but I cannot understand why is there an observance of large amplitude in longitudinal direction (Y). Can someone shed some light on this, looking at design and test setup? Would be grateful.

Regards

Why is it that I am observing a very high amplitude (more than 3g) in Y-direction and not in the Z-direction (which is the direction force is being applied)? I apply 0.4g at the base in vertical direction. Of course there are resonances in the test range, but I cannot understand why is there an observance of large amplitude in longitudinal direction (Y). Can someone shed some light on this, looking at design and test setup? Would be grateful.

Regards