JackAubrey

- 8

- 2

- TL;DR Summary

- Desire a a vortex in a vertical combustion tube, square vs round.

Greetings,

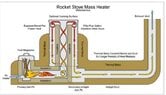

I am about to start experimenting with misnamed rocket stoves and rocket mass heaters. I say misnamed because I think the velocities are too slow to be rocket science. (Why would I experiment with these? Because I have cement, perlite, and reinforcement materials at hand and I just had hip surgery so I cannot get around so spryly at the moment. TMI, sorry.)

Anyway I seem to recall from circa 1976 that at low velocities a square pipe and a round pipe of the same dimension (8") would serve equally well for axial flow but I want a swirling flow in a vertical pipe. So I wonder how well a vortex can be maintained in a square tube especially where the Reynolds number of the cob like material is so horrible. I may find out empirically but would like to know what to expect.

This is another occasion where I wish I had elected fluid dynamics as an option course. I sure did enjoy 2 semesters of physics though. This is my first post to your forum so please forgive my awkward style, etc.

Thank you.

I am about to start experimenting with misnamed rocket stoves and rocket mass heaters. I say misnamed because I think the velocities are too slow to be rocket science. (Why would I experiment with these? Because I have cement, perlite, and reinforcement materials at hand and I just had hip surgery so I cannot get around so spryly at the moment. TMI, sorry.)

Anyway I seem to recall from circa 1976 that at low velocities a square pipe and a round pipe of the same dimension (8") would serve equally well for axial flow but I want a swirling flow in a vertical pipe. So I wonder how well a vortex can be maintained in a square tube especially where the Reynolds number of the cob like material is so horrible. I may find out empirically but would like to know what to expect.

This is another occasion where I wish I had elected fluid dynamics as an option course. I sure did enjoy 2 semesters of physics though. This is my first post to your forum so please forgive my awkward style, etc.

Thank you.