- #1

jtdrexel

- 7

- 1

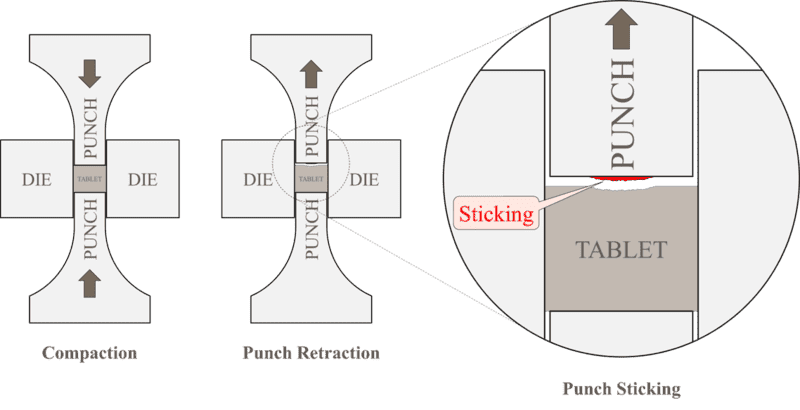

Pharmaceutical tablets are formed by compressing powder in a die by metal punches until a compact is formed. The term ‘Sticking’ refers to a phenomenon that results in the adherence of material onto the punch faces and die wall even after the metal has left contact with the tablet. I am interested in getting opinions and recommendations from this scientific community on what you think is causing ‘Sticking’ and how to test or study the fundamental mechanisms by which this occurs. A brief introduction into this problem is appended below if you wish to know more on this.

A brief introduction on 'Sticking'

One of the most common oral solid dosage forms is the tablet, like TUMS® or TYLENOL®. Tablets are formed by compressing powder in a die by metal punches until a compact is formed. It sounds easy, but tablet compaction is often met with all kinds of issues that result in the formation of tablet defects. For example: air entrapment in the compacting powder, improper filling of the die, inhomogeneity of the density distribution in the compact, various kinds of breakage of the tablet after its been compacted and/or ejected, etc.

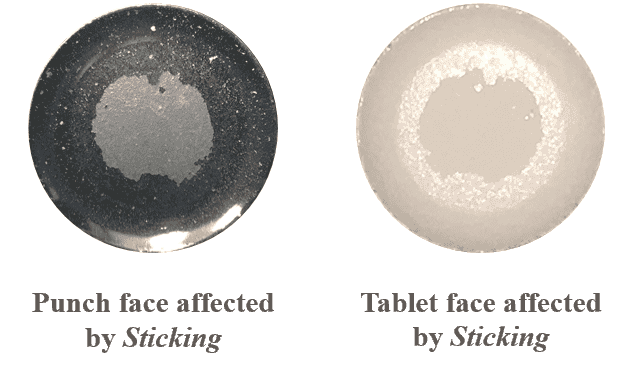

One of the type of tablet defects that I study is called ‘Sticking’. The term ‘Sticking’ refers to a phenomenon that results in the adherence of material onto the punch faces and die wall even after the metal has left contact with the tablet. Meaning, pieces of the tablet remain stuck on the punch face as the punch retracts off the tablet surface after it is compacted. This issue produces tablets with defective surfaces and ends up costing lots of time, money and delays to supplying medicines to patients.

Typically, the powder that is compacted into a tablet consists of at least three main components: the active drug crystals (like acetaminophen in TYLENOL®), a very small quantity of solid lubricant (like magnesium stearate to improve the flow properties of the powder) and a filler material (like microcrystalline cellulose). To give you an idea, the composition of the powder may be 20:79:1 drug:filler:lubricant.

Sticking is often a very gradual process. Meaning, you may see that the punch tip appears clean even after making 100 tablets but then it slowly forms a very faint powdery deposit after making ~500 tablets which will continue to accumulate and eventually become a clearly visible film. Typically, the adhered material is almost entirely composed of the drug. There are several factors known and/or hypothesized to play a role in the phenomenon of ‘Sticking’. Some of these include: particle size, morphology, melt temperature of drug, crystal fragmentation, interaction energies between crystal facets and metal surface, triboelectric charging, crystalline to amorphous transformation upon deformation, moisture, punch surface roughness… and the list goes on. For this reason, ‘Sticking’ is known to be a complex multi-faceted issue that can be caused by various factors contributing at once.

To date, there is no concrete understanding of ‘Sticking’ and how to mitigate this issue. In fact, many of the solutions are sort of shoot-in-the-dark not-so-scientific approaches which may work for one kind of drug and not for another. I am interested in getting opinions and recommendations from this scientific community on what you think is causing ‘Sticking’ and how to test or study the fundamental mechanisms by which this occurs. I would also love to get feedback from folks with different academic and industrial backgrounds than mine to help sort of think-outside-the-box.

A brief introduction on 'Sticking'

One of the most common oral solid dosage forms is the tablet, like TUMS® or TYLENOL®. Tablets are formed by compressing powder in a die by metal punches until a compact is formed. It sounds easy, but tablet compaction is often met with all kinds of issues that result in the formation of tablet defects. For example: air entrapment in the compacting powder, improper filling of the die, inhomogeneity of the density distribution in the compact, various kinds of breakage of the tablet after its been compacted and/or ejected, etc.

One of the type of tablet defects that I study is called ‘Sticking’. The term ‘Sticking’ refers to a phenomenon that results in the adherence of material onto the punch faces and die wall even after the metal has left contact with the tablet. Meaning, pieces of the tablet remain stuck on the punch face as the punch retracts off the tablet surface after it is compacted. This issue produces tablets with defective surfaces and ends up costing lots of time, money and delays to supplying medicines to patients.

Typically, the powder that is compacted into a tablet consists of at least three main components: the active drug crystals (like acetaminophen in TYLENOL®), a very small quantity of solid lubricant (like magnesium stearate to improve the flow properties of the powder) and a filler material (like microcrystalline cellulose). To give you an idea, the composition of the powder may be 20:79:1 drug:filler:lubricant.

Sticking is often a very gradual process. Meaning, you may see that the punch tip appears clean even after making 100 tablets but then it slowly forms a very faint powdery deposit after making ~500 tablets which will continue to accumulate and eventually become a clearly visible film. Typically, the adhered material is almost entirely composed of the drug. There are several factors known and/or hypothesized to play a role in the phenomenon of ‘Sticking’. Some of these include: particle size, morphology, melt temperature of drug, crystal fragmentation, interaction energies between crystal facets and metal surface, triboelectric charging, crystalline to amorphous transformation upon deformation, moisture, punch surface roughness… and the list goes on. For this reason, ‘Sticking’ is known to be a complex multi-faceted issue that can be caused by various factors contributing at once.

To date, there is no concrete understanding of ‘Sticking’ and how to mitigate this issue. In fact, many of the solutions are sort of shoot-in-the-dark not-so-scientific approaches which may work for one kind of drug and not for another. I am interested in getting opinions and recommendations from this scientific community on what you think is causing ‘Sticking’ and how to test or study the fundamental mechanisms by which this occurs. I would also love to get feedback from folks with different academic and industrial backgrounds than mine to help sort of think-outside-the-box.