- #1

RCH

- 6

- 1

- TL;DR Summary

- How to pump a fluid with suspended particles, without damaging them?

Hello --

I am working on a project where I need to recirculate a fluid which has a large quantity of glass spheres of say, 1mm diameter suspended in it, but without the pump crushing the spheres. I would appreciate any advice.

To give a simple description of the desired function: it will be a closed system with a vertically-oriented tank about 1m tall by 75cm wide, whose front and back are two sheets of glass spaced a few mm apart. The suspension will enter the tank at either the top or the bottom and will flow to the opposite end of the tank where it will collect and be pumped up (or down) about 1.5m, to start the process again. (That extra 50cm is to account for curved entry / exit tubes, rather than elbows, to use gravity to prevent the spheres from their expected tendency to collect in elbows.) As you might suspect, there is a bit more to the project than that, but that is the gist of it. The real goal is to move the glass spheres; the fluid is just there to act as a circulatory medium.

I don't know yet what fluid would be optimal for this suspension, but the spheres will likely be denser than it, which could affect the spheres' behavior with various pump types.

I have three main concerns: the primary one is to avoid crushing the glass spheres into dust by the mechanical action of the pump on them. The secondary concern is avoiding the spheres causing wear to the pump's parts where they come in contact; I want this to be low-maintenance. And the tertiary is to make it as quiet as possible. It seems to me that impeller pumps might be prone to the first two problems. A diaphragm pump doesn't seem practical here, and I don't want to use anything that reciprocates, due to the noise and vibration. It seems to me that a peristaltic pump would almost certainly cause crushing of the spheres.

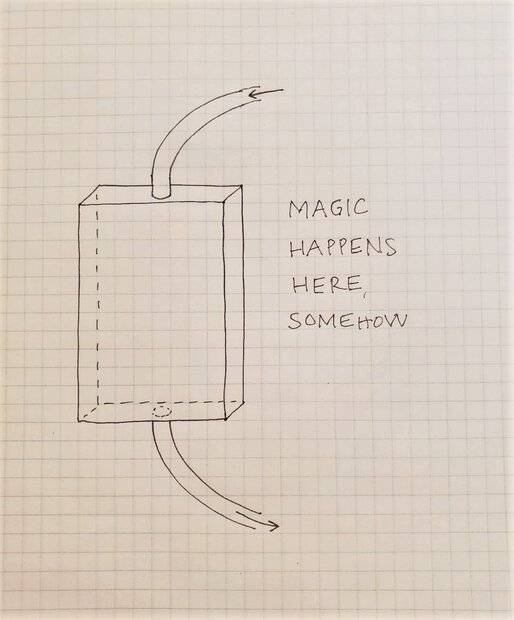

Perhaps some version of an Archimedes' screw would be a good choice for avoiding crushing the spheres, and since the suspension has to be moved vertically about 1.5m, their long, cylindrical configuration might be a plus. The "Olds Elevator" is interesting as well, but rotating the cylinder, rather than the augur, might not actually give significant advantages over rotating the augur, and might add complexity ( ). Perhaps an augur and cylinder that are in one piece, the augur of which has "steps" or "buckets" formed into it to help collect the spheres, would be better than the standard screw?

I love the idea of a magnetohydrodynamic pump (no moving parts!), but I doubt that the glass spheres could be convinced to move along with the fluid (but it might be interesting to try anyway).

I'd welcome any constructive opinions!

Thanks --

Robert

I am working on a project where I need to recirculate a fluid which has a large quantity of glass spheres of say, 1mm diameter suspended in it, but without the pump crushing the spheres. I would appreciate any advice.

To give a simple description of the desired function: it will be a closed system with a vertically-oriented tank about 1m tall by 75cm wide, whose front and back are two sheets of glass spaced a few mm apart. The suspension will enter the tank at either the top or the bottom and will flow to the opposite end of the tank where it will collect and be pumped up (or down) about 1.5m, to start the process again. (That extra 50cm is to account for curved entry / exit tubes, rather than elbows, to use gravity to prevent the spheres from their expected tendency to collect in elbows.) As you might suspect, there is a bit more to the project than that, but that is the gist of it. The real goal is to move the glass spheres; the fluid is just there to act as a circulatory medium.

I don't know yet what fluid would be optimal for this suspension, but the spheres will likely be denser than it, which could affect the spheres' behavior with various pump types.

I have three main concerns: the primary one is to avoid crushing the glass spheres into dust by the mechanical action of the pump on them. The secondary concern is avoiding the spheres causing wear to the pump's parts where they come in contact; I want this to be low-maintenance. And the tertiary is to make it as quiet as possible. It seems to me that impeller pumps might be prone to the first two problems. A diaphragm pump doesn't seem practical here, and I don't want to use anything that reciprocates, due to the noise and vibration. It seems to me that a peristaltic pump would almost certainly cause crushing of the spheres.

Perhaps some version of an Archimedes' screw would be a good choice for avoiding crushing the spheres, and since the suspension has to be moved vertically about 1.5m, their long, cylindrical configuration might be a plus. The "Olds Elevator" is interesting as well, but rotating the cylinder, rather than the augur, might not actually give significant advantages over rotating the augur, and might add complexity ( ). Perhaps an augur and cylinder that are in one piece, the augur of which has "steps" or "buckets" formed into it to help collect the spheres, would be better than the standard screw?

I love the idea of a magnetohydrodynamic pump (no moving parts!), but I doubt that the glass spheres could be convinced to move along with the fluid (but it might be interesting to try anyway).

I'd welcome any constructive opinions!

Thanks --

Robert

Last edited by a moderator:

)

)