- #1

M110020

- 3

- 0

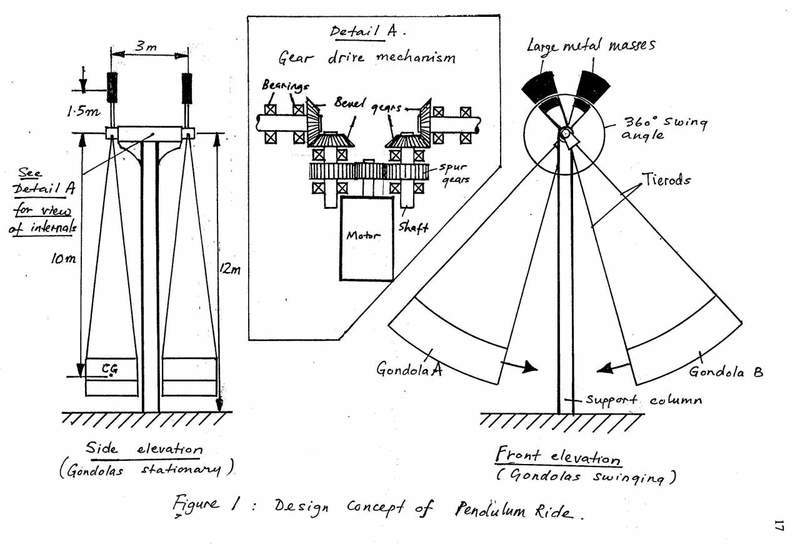

Hi guys. I saw this in one of my Engineering Design slides about embodiment designs and saw these slides using uniform stresses as an example and had a hard time figuring out how is this structure supposed to ensure uniform stress.

Shown in here is taken from the slides I was referring to. What I can't seem to grasp is if the shape of the gondolas are wedges doesn't that make all the stresses concentrate at one point on the structure? I thought that was a bad thing as stress concentration can be extremely destructive for a structure.

Could someone maybe explain it in brief to me or maybe point me in the right direction? Thanks a million.

Shown in here is taken from the slides I was referring to. What I can't seem to grasp is if the shape of the gondolas are wedges doesn't that make all the stresses concentrate at one point on the structure? I thought that was a bad thing as stress concentration can be extremely destructive for a structure.

Could someone maybe explain it in brief to me or maybe point me in the right direction? Thanks a million.