Ian K

- 2

- 2

- TL;DR Summary

- How to calculate outward force of workbench top with slopping leg

Hello,

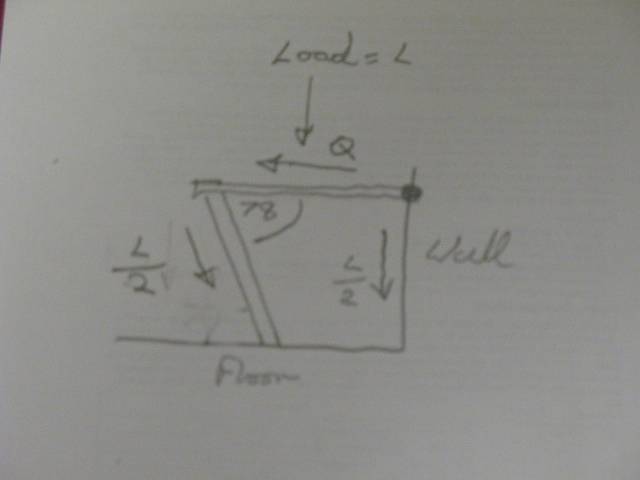

I am making a workbench for my mancave, the front edge of the bench is supported by legs that slopes inwards at 78 degrees and the back/rear edge of the bench top is fixed to the wall. How do I calculate the force Q pulling the bench top away from the wall please?

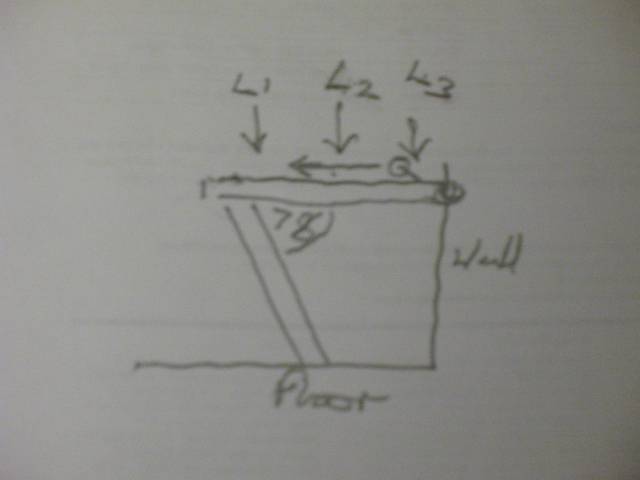

Also is the force Q affected by the position of a load on the worktop? eg L1 is quarter distance from front, L2 is in the middle and L3 is three quarters distance from the front. See attached photos of sketches.

Many thanks in advance Ian K

PS I assume L/2 is correct for the shared vertical load supports (Leg and Wall)

I am making a workbench for my mancave, the front edge of the bench is supported by legs that slopes inwards at 78 degrees and the back/rear edge of the bench top is fixed to the wall. How do I calculate the force Q pulling the bench top away from the wall please?

Also is the force Q affected by the position of a load on the worktop? eg L1 is quarter distance from front, L2 is in the middle and L3 is three quarters distance from the front. See attached photos of sketches.

Many thanks in advance Ian K

PS I assume L/2 is correct for the shared vertical load supports (Leg and Wall)

Last edited by a moderator: