Frabjous said:

1) Your projectile will weigh more

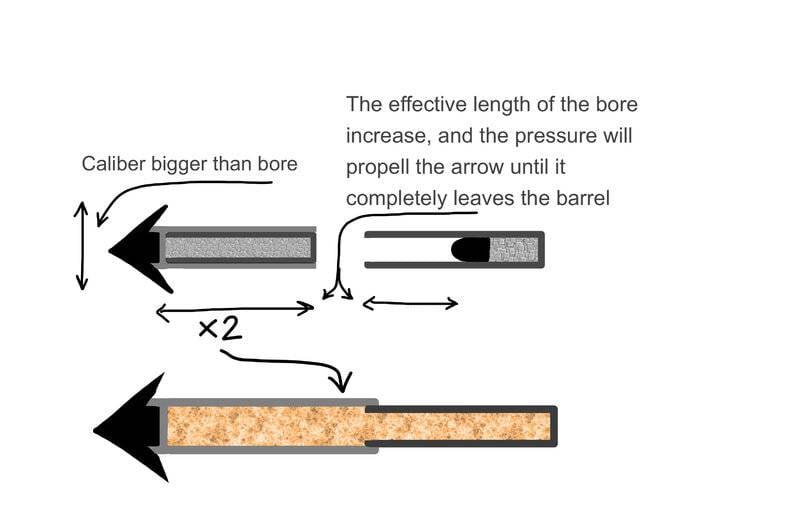

2) Your effective barrel diameter will be larger so pressure will decay faster

3) Tumbling will be a problem

4) You have to load two things not one

5) In the normal gun, your unburnt powder takes up an unrealisticly large percentage of the barrel. Correcting this will not help your design.

1, not necessary, it depends on the material it’s made of. Short crossbow bolts are about the same weight as a 9mm bullet, and those bolts are over 4 inch long, the projectile in my design is only 2 inch. However since it will contain pressure, does it have to be as strong as the barrel? Or will the pressure curve be low enough and the force not as directed towards the walls at the point when it reaches the hollow projectile, to allow it to be weaker? If it has to be made of steel to be strong enough, depending on thickness and length the weight might be an issue. Looking at how thin revolver chambers are, I think they could be made thin enough for weight not being an issue.

2, yes, I don’t think this will be a problem though, and if a charge would be to small, it can simply be increased to compensate for the larger diameter.

3, the arrow airgun was very accurate, it used front heavy arrows with fletching. Will the short barrel in my gunpowder design make it less accurate?

4, this is true. But why didn’t they use this concept in muzzleloaded pistols? Black powder burn slower than smokeless, so they had to use longer barrels back then compared to today. For small black powder pistols with low velocity due to short barrel, like the Philadelphia derringer, this concept would’ve been a great improvement?

5, look at a snubnose revolver for example, the cartridge basically take up that much space. The chamber is as long as the barrel. With fast smokeless powder it’s not as big of an issue as it was with black powder. However the concept of my design still holds true?