piyushverma

- 1

- 1

- TL;DR Summary

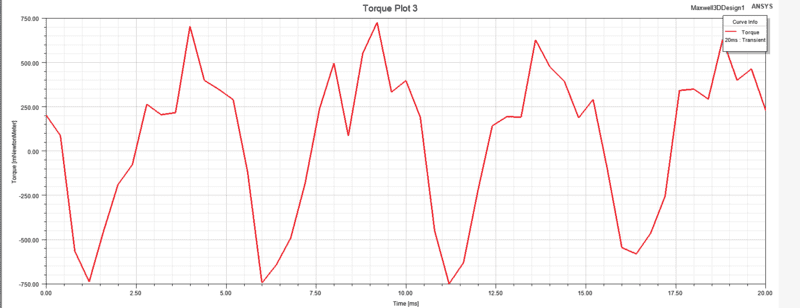

- while simulation for a PM axial flux generator at no load 1000RPM, shows moving torque fluctuating between -0.7 to 0.7 Nm, which should have been 0, as there is no load attached and it is coreless design so no cogging torque as well. Need someone to help me out.

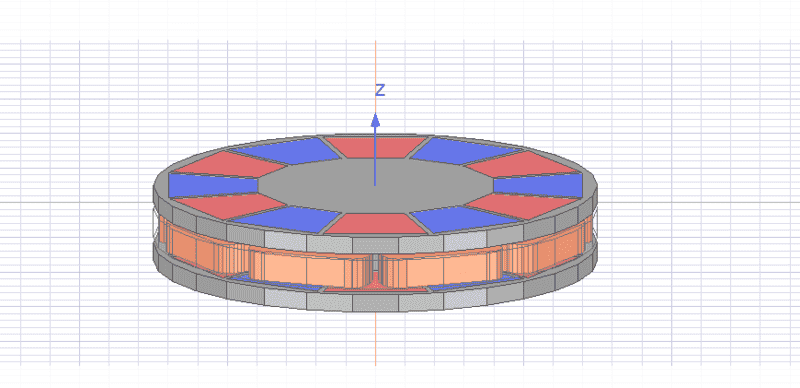

I am working on an axial flux generator design, I consisits of 2 rotors and one stator, there are 6 pole pairs and 9 coils. Here is my simulation setup

The three phase windings are connected in star configuration through Maxwell circuit.

I created two bands enclosing each rotor and then united them to assign a single band for both rotor which is set to rotational motion at 1000RPM constant. I am getting satisfactory results for output voltages, what I don't understand is this torque curve

currently the stator material is air ( I switched to air after setting it initially to electrical steel laminated, which resulted in 2Nm peaks in torque).

I don't understand the reason for this torque as there is no core so no cogging torque and also there is no load connected.

I am stuck, Kindly help :(

The three phase windings are connected in star configuration through Maxwell circuit.

I created two bands enclosing each rotor and then united them to assign a single band for both rotor which is set to rotational motion at 1000RPM constant. I am getting satisfactory results for output voltages, what I don't understand is this torque curve

currently the stator material is air ( I switched to air after setting it initially to electrical steel laminated, which resulted in 2Nm peaks in torque).

I don't understand the reason for this torque as there is no core so no cogging torque and also there is no load connected.

I am stuck, Kindly help :(