paradisePhysicist

- 143

- 18

I am trying to build a dual input (double input) crankshaft, out of Lego. All the tutorials online use flywheels, but I want a strong high quality crankshaft that doesn't rely on flywheels.

The crankshaft is for a 1 cylinder or sinusoidal linear type input. This video demonstrates the flaw of the current crankshafts:

Wikipedia (gif animation) makes the crankshafts look nice, perfect and smooth. But IRL the crankshafts commonly jam like the video above if you try to use linear input.

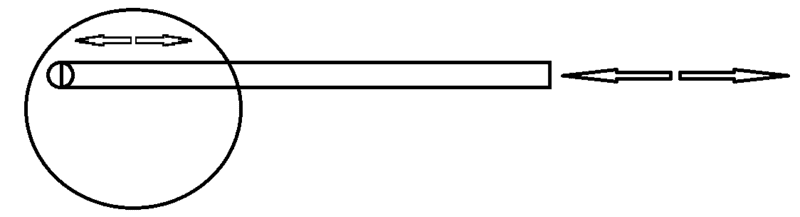

I can explain what is wrong with the crankshafts in this picture.

The arm only travels 179 degrees, the arm can never travel 181 degrees in order to get to the other side (unless the device is very precisely optimized and helped with flywheel). Therefore it only push-pulls the rotation instead of giving a full rotation. In practice, it actually gets jammed often around the 175 degree region, perhaps due to material warping or length axis torque.

Even though I see the problem, I haven't yet invented a solution. I am looking for neat ideas of how to build a better crankshaft. For instance, a Tesla valve is a neat idea for valves, I would like something equivalent in neatness to that. Something robust, not overly complicated, and efficient. The video comment section makes vague references to steam engines fixing this shortcoming, but that sounds like an air mechanism and additional power and complexity is needed, I am looking to just add a couple of extra levers or gears.

The crankshaft is for a 1 cylinder or sinusoidal linear type input. This video demonstrates the flaw of the current crankshafts:

Wikipedia (gif animation) makes the crankshafts look nice, perfect and smooth. But IRL the crankshafts commonly jam like the video above if you try to use linear input.

I can explain what is wrong with the crankshafts in this picture.

The arm only travels 179 degrees, the arm can never travel 181 degrees in order to get to the other side (unless the device is very precisely optimized and helped with flywheel). Therefore it only push-pulls the rotation instead of giving a full rotation. In practice, it actually gets jammed often around the 175 degree region, perhaps due to material warping or length axis torque.

Even though I see the problem, I haven't yet invented a solution. I am looking for neat ideas of how to build a better crankshaft. For instance, a Tesla valve is a neat idea for valves, I would like something equivalent in neatness to that. Something robust, not overly complicated, and efficient. The video comment section makes vague references to steam engines fixing this shortcoming, but that sounds like an air mechanism and additional power and complexity is needed, I am looking to just add a couple of extra levers or gears.