go2255

- 11

- 0

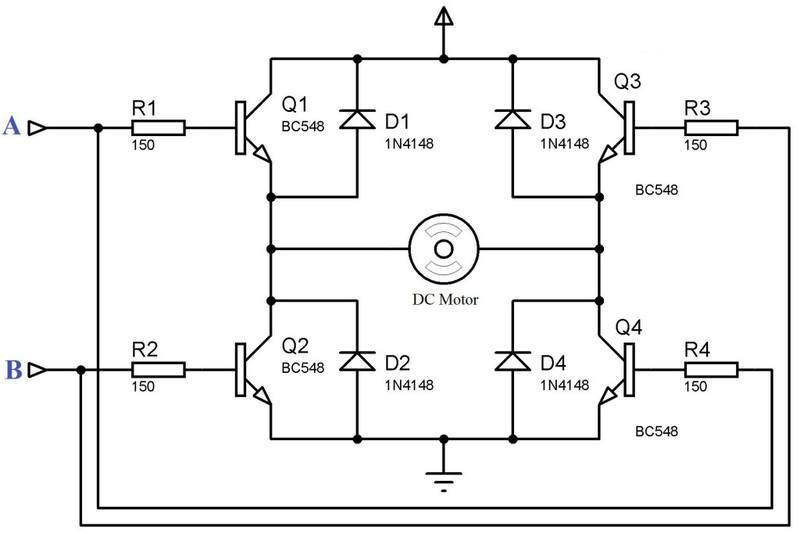

I want to design a bidirectional DC motor ,

so use four transistors in the H bridge circuit.

I can understand the first circuit,

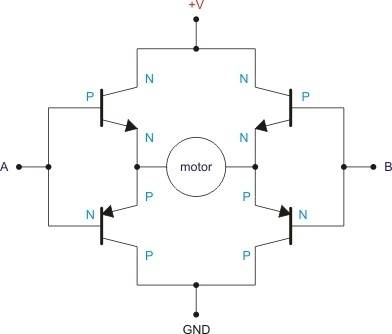

but for the second, I can't understand why input signal ,

eg: A, is connected to the same side of transistors?

What is the differences, which one I should choose?

1.

2.

so use four transistors in the H bridge circuit.

I can understand the first circuit,

but for the second, I can't understand why input signal ,

eg: A, is connected to the same side of transistors?

What is the differences, which one I should choose?

1.

2.