Pinon1977

- 126

- 4

- TL;DR Summary

- Trying to determine if you can estimate the efficiency of a system with a derived known efficiency as the reference starting point.

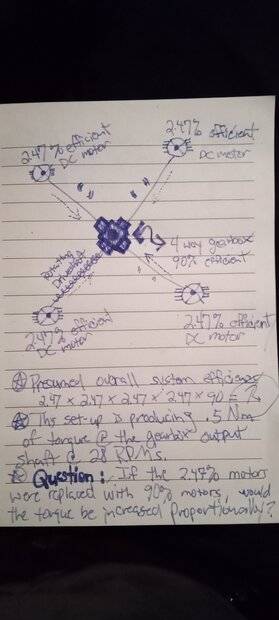

Please see the attempt sketch. Basically I have four very inefficient DC motors all commonly turning a single drive shaft at the center of the system. Currently these motors that are 2.47% efficient individually able to produce 5 newton meters of torque at 28 RPMs. So my question is this. If I replace those 2.47% efficient motors with a motor that is exactly the same but 90% efficient, can I use a multiplier of 36.4 to roughly estimate what the new torque value would be? (.5 Nm * 36.4 = 18.4 Nm)

Last edited by a moderator: