Majeedoz

- 3

- 0

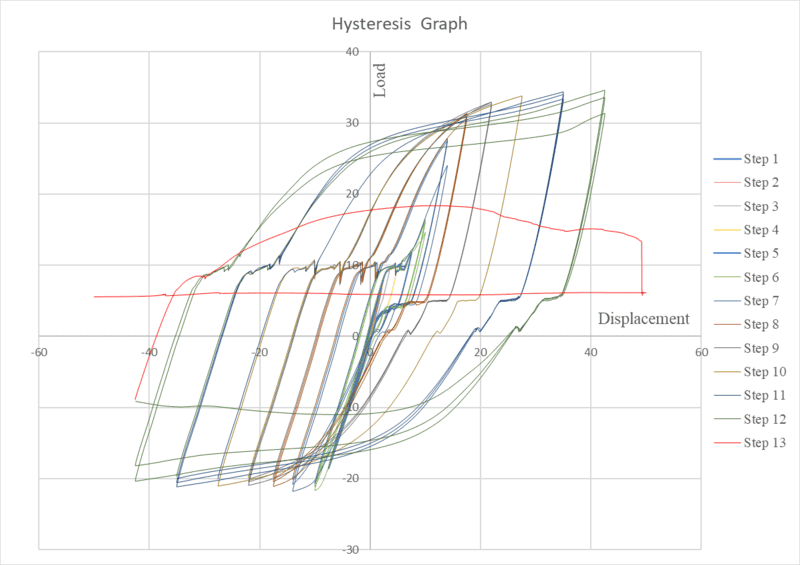

TL;DR Summary: I have experimented metal bars under cyclic load, you can find the picture attached of the hysteresis loops of "Load vs displacement" of the experimental work... 13 steps (each step 3 cycles)

Now I want to find the point where the steel started yielding and the yield strength so I can calculate dissipated energy and stiffness and also the damping ratio.

If you have an idea, please help, I may provide more details if needed.

Appreciate your help.

Now I want to find the point where the steel started yielding and the yield strength so I can calculate dissipated energy and stiffness and also the damping ratio.

If you have an idea, please help, I may provide more details if needed.

Appreciate your help.