Calafalas

- 2

- 0

Hi chemistry friends,

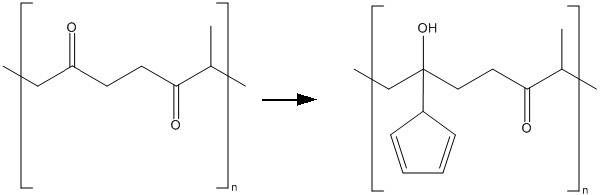

I'm currently working on a reaction to produce the following polymer: Cyclopentadiene functionalized polyketone.

I start with polyketone as a reagent and I should end up with the reaction product together with the solvent (THF) and water with NaOH.

My question is as following: How can I separate my reaction product from the THF/water ?

Do you think that is will be insoluble in THF/water, so I can use simple filtration? Or should I use a different solvent to extract the polymer ?

I'm currently working on a reaction to produce the following polymer: Cyclopentadiene functionalized polyketone.

I start with polyketone as a reagent and I should end up with the reaction product together with the solvent (THF) and water with NaOH.

My question is as following: How can I separate my reaction product from the THF/water ?

Do you think that is will be insoluble in THF/water, so I can use simple filtration? Or should I use a different solvent to extract the polymer ?