Mohmmad Maaitah

- 90

- 20

- Homework Statement

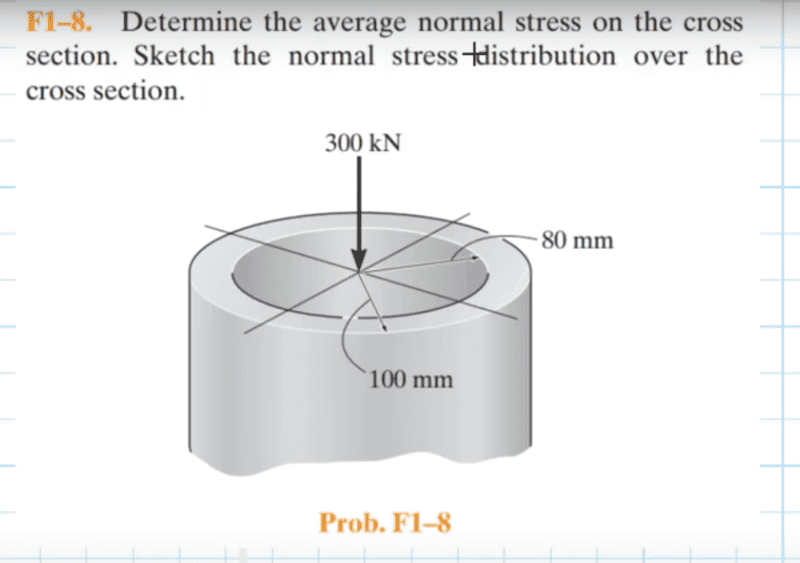

- Determine the average normal stress on the cross

section. Sketch the normal stress distribution over the

cross section.

- Relevant Equations

- σ = F/A

Hi, I've problem thinking about this problem

isn't the force acting on "nothing"?

how can there be any stress, I'm lost!

isn't the force acting on "nothing"?

how can there be any stress, I'm lost!