zand10000

- 6

- 2

- TL;DR Summary

- In Simulation of transformer and electrical motors in software like ansys maxwell we usually have to model conductors, but does it matter how to draw them?

In Simulation of transformer and electrical motors in software like ansys maxwell we usually have to model conductors, but does it matter how to draw them?

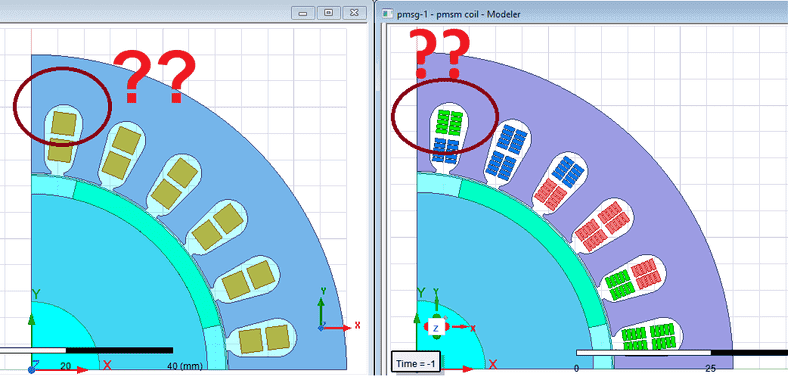

I use Ansys software for finite element simulations. Maxwell, Simplorer, RMXpert and other toolboxes. but I always have a doubt on how to model a coil?! should we use a single geometry as a whole coil or we should draw wires one by one! but even if we could, what should we do about twisted litz wires? it is almost impossible to model them in real shape.

what consideration should have in modeling?

I hope electrical engineers help to have a useful conclusion.

I use Ansys software for finite element simulations. Maxwell, Simplorer, RMXpert and other toolboxes. but I always have a doubt on how to model a coil?! should we use a single geometry as a whole coil or we should draw wires one by one! but even if we could, what should we do about twisted litz wires? it is almost impossible to model them in real shape.

what consideration should have in modeling?

I hope electrical engineers help to have a useful conclusion.

Last edited by a moderator: