canuck123

- 17

- 8

Hello, I am a chemistry intern currently running a project that involves both chemistry and electromagnetism. Bottom line, I'm a little out of my depth and have much to learn, and I'm having a bit of trouble with the coils I constructed.

My setup will consist of four coils positioned horizontally around a microscope objective, and one underneath, such that the coils opposite each other will create a homogeneous field in the center, with a downwards gradient from the lower magnet. distance between opposite coils will be approximately 3 inches, so that's why I believed an iron core would be needed to achieve 15mT at the center.

I machined aluminum bobbins to act as a heat sink for the coil, as I'm fairly certain the aluminum shouldn't affect the field at all, although I do have delrin that I could use instead. For the cores, I bought some VIM VAR core iron (99.85-99.9% Fe, less than 0.01% C), machined them to press fit in the bobbins, and had the magnetically annealed in wet hydrogen to homogenize and maximize the relative permeability.

The relative permeability is supposed to reach as high as 15000 with the heat treating, imagine my surprise when the flux density was only 2.5x stronger with the core inserted. A current of 1.4A yields a flux density of 40 gauss at the mouth of the bobbin with air core, and 100 gauss with the iron core inserted.

My own calculations, as well as an online calculator I used from the company I bought the current amplifiers from, told me I should be easily able to achieve my desired field strengths, so this leads me to believe I either built something wrong, or was sold the wrong material.

Is this something that you guys would be able to help with, or is there a better forum for this?

EDIT: Here are images of my current coil that I'm troubleshooting:

It is currently 175 turns of 20AWG enameled magnet wire, but I have different wire gauges and stock to make bobbins from, so I can make more or less turns if needed.

Here is a screenshot of the calculator I've been using to help me. It's called a helmholtz calculator, but it works for any distance to radius ratio as you can input the distance yourself. The link to calculator is https://www.accelinstruments.com/Helmholtz-Coil/Helmholtz-coil-calculator.html

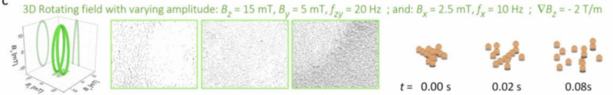

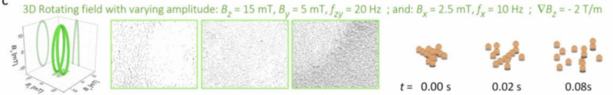

Here are some screenshots from a study I am trying to replicate. They detail the field shape and field strengths, frequencies, as well as the setup they used.

The experiment involves an elliptical rotating field out of plane generated by the Z and Y coils, with an additional AC field at a different frequency applied in the X axis.

My setup will consist of four coils positioned horizontally around a microscope objective, and one underneath, such that the coils opposite each other will create a homogeneous field in the center, with a downwards gradient from the lower magnet. distance between opposite coils will be approximately 3 inches, so that's why I believed an iron core would be needed to achieve 15mT at the center.

I machined aluminum bobbins to act as a heat sink for the coil, as I'm fairly certain the aluminum shouldn't affect the field at all, although I do have delrin that I could use instead. For the cores, I bought some VIM VAR core iron (99.85-99.9% Fe, less than 0.01% C), machined them to press fit in the bobbins, and had the magnetically annealed in wet hydrogen to homogenize and maximize the relative permeability.

The relative permeability is supposed to reach as high as 15000 with the heat treating, imagine my surprise when the flux density was only 2.5x stronger with the core inserted. A current of 1.4A yields a flux density of 40 gauss at the mouth of the bobbin with air core, and 100 gauss with the iron core inserted.

My own calculations, as well as an online calculator I used from the company I bought the current amplifiers from, told me I should be easily able to achieve my desired field strengths, so this leads me to believe I either built something wrong, or was sold the wrong material.

Is this something that you guys would be able to help with, or is there a better forum for this?

EDIT: Here are images of my current coil that I'm troubleshooting:

It is currently 175 turns of 20AWG enameled magnet wire, but I have different wire gauges and stock to make bobbins from, so I can make more or less turns if needed.

Here is a screenshot of the calculator I've been using to help me. It's called a helmholtz calculator, but it works for any distance to radius ratio as you can input the distance yourself. The link to calculator is https://www.accelinstruments.com/Helmholtz-Coil/Helmholtz-coil-calculator.html

Here are some screenshots from a study I am trying to replicate. They detail the field shape and field strengths, frequencies, as well as the setup they used.

The experiment involves an elliptical rotating field out of plane generated by the Z and Y coils, with an additional AC field at a different frequency applied in the X axis.

Last edited: