MayZ91

- 23

- 0

Hello all,

Yet another problem on engineering mechanics. This time I have a spring loaded; counterpoised arm:

Something like this- http://www.akwmedical.com/files/imagecache/cart/SK2323_1.jpg

http://t3.gstatic.com/images?q=tbn:ANd9GcTUCvnSKhKEbs4uNiOLg2TGU3p0quUrSp8Uh4QXqt5m4eIEf6_ISA

What it consists of is a compression spring which compresses on articulation to keep the arm in place. Just like the old table lamps.

The set up goes like this:

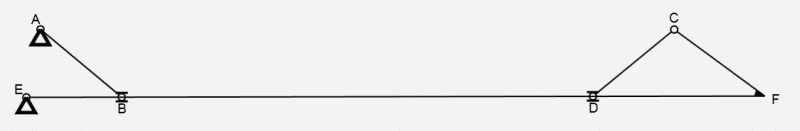

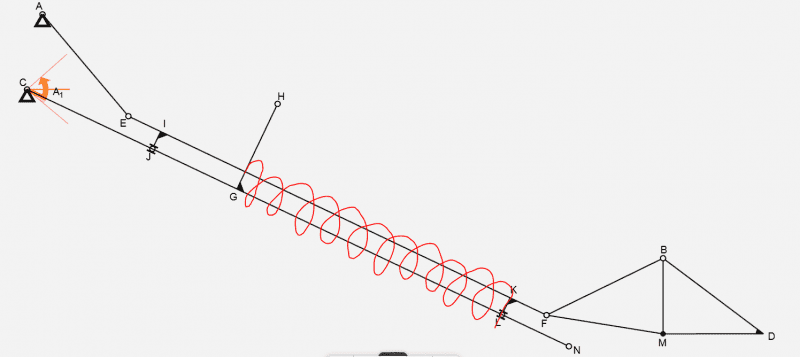

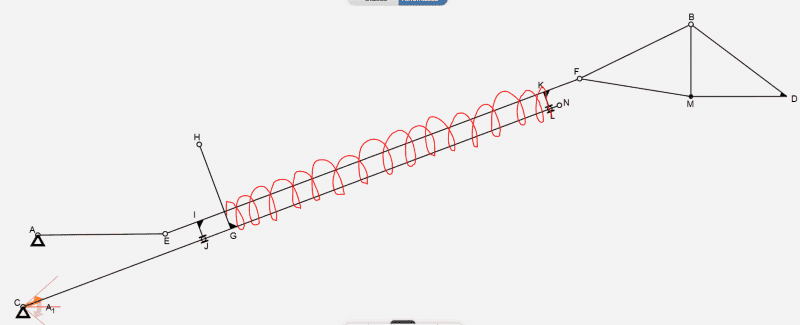

AB is a link which is connected to BD(spindle). The spindle BD is held concentric with the arm EF, which is a circular tube. The spindle BD has a sliding contact with arm EF. Similarly; link CD is connected to the same spindle at D. There is another sliding contact between the spindle BD and arm EF at D. The pin joints C and F are on a plate which carries a load W. Due to the sliding joints, when the arm EF rotates about E, the weight W is always perpendicular to the ground(these links behave like a parallelogram). To counterbalance the system, a spring is introduced between a stopper and joint D. The stopper is connected to the arm EF and welded. This spring is concentric with the spindle BD.

BELOW images(with spring) can be assumed for understanding the articulations only, it does not depict the actual scenario.

The problem is to identify the lift capacity for the system. The load is attached to point F (in the first figure) (all references are for figure 1)

The spring has the following parameters: Spring rate: 32 N/mm deflection: 58mm (for rotation of 40 deg above n below horizontal) Spring length: 450mm Spring set length: 363mm(set for 40deg above horizontal) 2790N for the spring set length and 4670N generated for 58mm deflection.

Not to worry about the wire dia and OD of the spring just yet.

Attached is the excel sheet with attempt to solution.

I am getting 800+N as the lift capacity. However, its not as high 350N. Need to know where I am going wrong.

Kindly help.

Thank you.

Yet another problem on engineering mechanics. This time I have a spring loaded; counterpoised arm:

Something like this- http://www.akwmedical.com/files/imagecache/cart/SK2323_1.jpg

http://t3.gstatic.com/images?q=tbn:ANd9GcTUCvnSKhKEbs4uNiOLg2TGU3p0quUrSp8Uh4QXqt5m4eIEf6_ISA

What it consists of is a compression spring which compresses on articulation to keep the arm in place. Just like the old table lamps.

The set up goes like this:

AB is a link which is connected to BD(spindle). The spindle BD is held concentric with the arm EF, which is a circular tube. The spindle BD has a sliding contact with arm EF. Similarly; link CD is connected to the same spindle at D. There is another sliding contact between the spindle BD and arm EF at D. The pin joints C and F are on a plate which carries a load W. Due to the sliding joints, when the arm EF rotates about E, the weight W is always perpendicular to the ground(these links behave like a parallelogram). To counterbalance the system, a spring is introduced between a stopper and joint D. The stopper is connected to the arm EF and welded. This spring is concentric with the spindle BD.

BELOW images(with spring) can be assumed for understanding the articulations only, it does not depict the actual scenario.

The problem is to identify the lift capacity for the system. The load is attached to point F (in the first figure) (all references are for figure 1)

The spring has the following parameters: Spring rate: 32 N/mm deflection: 58mm (for rotation of 40 deg above n below horizontal) Spring length: 450mm Spring set length: 363mm(set for 40deg above horizontal) 2790N for the spring set length and 4670N generated for 58mm deflection.

Not to worry about the wire dia and OD of the spring just yet.

Attached is the excel sheet with attempt to solution.

I am getting 800+N as the lift capacity. However, its not as high 350N. Need to know where I am going wrong.

Kindly help.

Thank you.