- #1

Imperatore

- 30

- 0

Hey there!

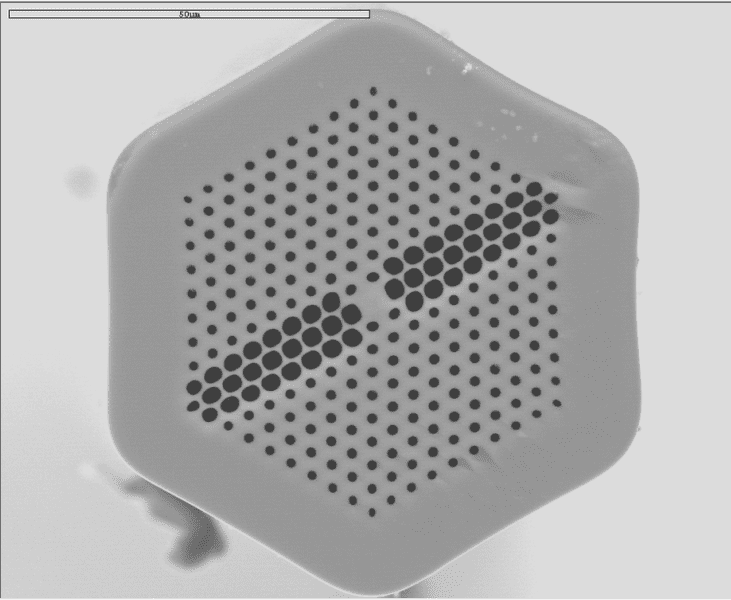

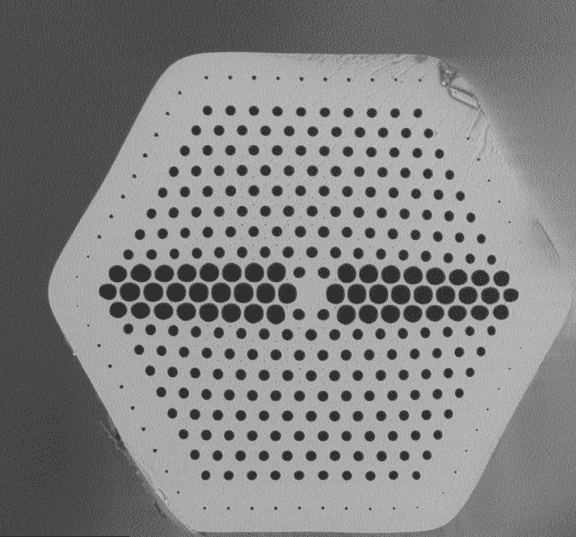

I got two pictures of PCF's cross sections.

Can anybody tell me if these PCF are the same? I mean, why there is an outer ring of smaller air holes in the pic 2, what does that ring represents? (core, cladding)

I got two pictures of PCF's cross sections.

Can anybody tell me if these PCF are the same? I mean, why there is an outer ring of smaller air holes in the pic 2, what does that ring represents? (core, cladding)