MetroEngineer

- 3

- 0

Hi,

I am wondering if it is possible to "piggyback" off existing meters/indicators in a diesel generator?

The generator has traditional analog 'VU' meters for voltage, current, and frequency. It also has standard analog gauge fuel meter, oil pressure, water temperature, rpm, and lamp/led indicators for overspeed, low oil pressure, low fuel level, battery charge, high water temperature and Earth leakage.

Ideally I would like to monitor all these readings, I have the MOXA AD convertors with analog (0-10V or 4-20mA) and digital (Logic 0 = 0-3V and Logic 1 = 10 to 30V) inputs. If I 'piggyback' off these device taking for example the voltage range that is applied to the fuel meter or the voltage applied to the lamp indicators will it affect the circuit? I realize that for the ammeter I would have to put it in series, if the current range is higher than the MOXA input I can just use a current transformer right?

I have the wiring diagram and the single line diagram but not the full schematic for this Japanese made generator. One colleague I spoke to said to not mess with the existing circuit and just add in the required metering (i.e. a new modbus output fuel meter etc), but it seems a waste when the relative signals are already there?

Is this possible?

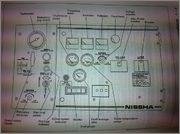

This is what the panel look like:

This is the back of the panel:

I am wondering if it is possible to "piggyback" off existing meters/indicators in a diesel generator?

The generator has traditional analog 'VU' meters for voltage, current, and frequency. It also has standard analog gauge fuel meter, oil pressure, water temperature, rpm, and lamp/led indicators for overspeed, low oil pressure, low fuel level, battery charge, high water temperature and Earth leakage.

Ideally I would like to monitor all these readings, I have the MOXA AD convertors with analog (0-10V or 4-20mA) and digital (Logic 0 = 0-3V and Logic 1 = 10 to 30V) inputs. If I 'piggyback' off these device taking for example the voltage range that is applied to the fuel meter or the voltage applied to the lamp indicators will it affect the circuit? I realize that for the ammeter I would have to put it in series, if the current range is higher than the MOXA input I can just use a current transformer right?

I have the wiring diagram and the single line diagram but not the full schematic for this Japanese made generator. One colleague I spoke to said to not mess with the existing circuit and just add in the required metering (i.e. a new modbus output fuel meter etc), but it seems a waste when the relative signals are already there?

Is this possible?

This is what the panel look like:

This is the back of the panel:

Last edited: