anima

- 3

- 0

- TL;DR Summary

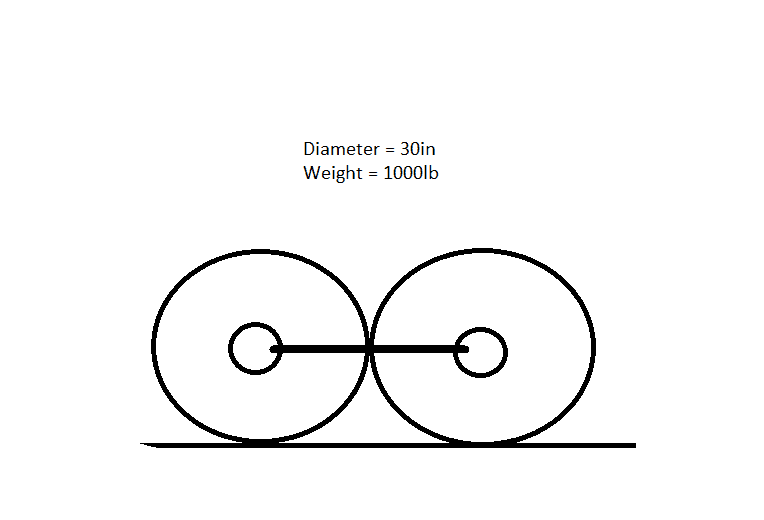

- Hello, I am trying to figure the strength (in lbs) of a strap needed to attach 2 Rolls together without breaking. Each wheel has a weight of 1000lbs and a diameter of 30in. Assume each roll is a perfect circle.

Hello, I am trying to figure the strength (in lbs) of a strap needed to attach 2 Rolls together without breaking. Each wheel has a weight of 1000lbs and a diameter of 30in. If there is required information missing, let me know.