inkblotch

- 5

- 2

- TL;DR Summary

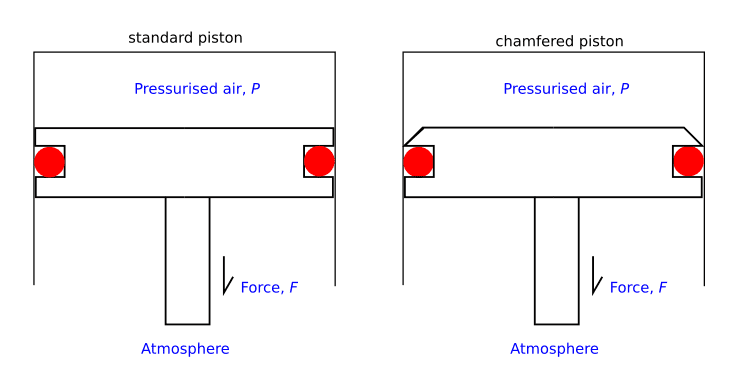

- What happens to the resulting force in a pneumatic cylinder, if the piston inside were chamfered.

I was reading up on forces on hydraulic/pneumatic cylinders, and I've been thinking of this for a while:

So for a pneumatic cylinder, the force on the piston is simply:

P = F/a

F = P x a

where a = area of the piston that the air pressure is acting on.

So what would happen if the piston is chamfered, thus increasing the surface area?

See above, (red circles are o-rings). In a closed system, my guess is :

Edit : The next step is, given the same air pressure, how could we estimate the increase in downward force?

So for a pneumatic cylinder, the force on the piston is simply:

P = F/a

F = P x a

where a = area of the piston that the air pressure is acting on.

So what would happen if the piston is chamfered, thus increasing the surface area?

See above, (red circles are o-rings). In a closed system, my guess is :

- The overall volume has increased, decreasing the pressure inside

- However, surface area is increased due to the chamfer

- Therefore the resulting downward force is the same.

Edit : The next step is, given the same air pressure, how could we estimate the increase in downward force?

Last edited: