- #1

Spinnor

Gold Member

- 2,226

- 431

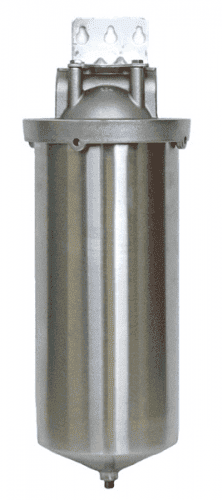

Bought a stainless steel whole house water filter for a very good price ($100), turns out too good. On inspection I suspected it would leak so rather then installing it into the house water system I pressure tested it. There was a small leak that stopped after a minute or so. Relieve the pressure and repressureize and the leak came back and stopped as before after a minute or so. I am guessing the o-ring slowly deforms to fill the void in the shell. An image of the unit follows,

The tall can shaped part has a vertical seam weld on the inside that was ground smooth where the o-ring touches but done with a grinding stone with a significantly smaller radius then the inner radius of the shell. I am pretty sure that is where the leak is coming from.

The store I bought it from are willing to take my unit back and replace it with one that hopefully does not leak but I am sure there is a cleaver fix that involves some type of epoxy. The following is how I thought of fixing it where the inside weld of the shell was ground down a bit too much I would apply just the right amount of epoxy, not too much not too little. Then I would cover the epoxy with a piece of rather thickish clear tape and smooth out the epoxy with the straight edge of a credit card. If the tape didn't work the same idea but using a small thin piece of oiled aluminum might do the trick.

I will probably end up shipping it back but if you had to make the repair with a limited tool set what might you do?

Any suggestions for the type of epoxy to use? We have slightly acidic water.

Thanks for any thoughts.

The tall can shaped part has a vertical seam weld on the inside that was ground smooth where the o-ring touches but done with a grinding stone with a significantly smaller radius then the inner radius of the shell. I am pretty sure that is where the leak is coming from.

The store I bought it from are willing to take my unit back and replace it with one that hopefully does not leak but I am sure there is a cleaver fix that involves some type of epoxy. The following is how I thought of fixing it where the inside weld of the shell was ground down a bit too much I would apply just the right amount of epoxy, not too much not too little. Then I would cover the epoxy with a piece of rather thickish clear tape and smooth out the epoxy with the straight edge of a credit card. If the tape didn't work the same idea but using a small thin piece of oiled aluminum might do the trick.

I will probably end up shipping it back but if you had to make the repair with a limited tool set what might you do?

Any suggestions for the type of epoxy to use? We have slightly acidic water.

Thanks for any thoughts.