Uncanny3

- 8

- 1

Hi,

I want to share my thought on what I have called a 'subducing head',

it's a pneumatic engine.

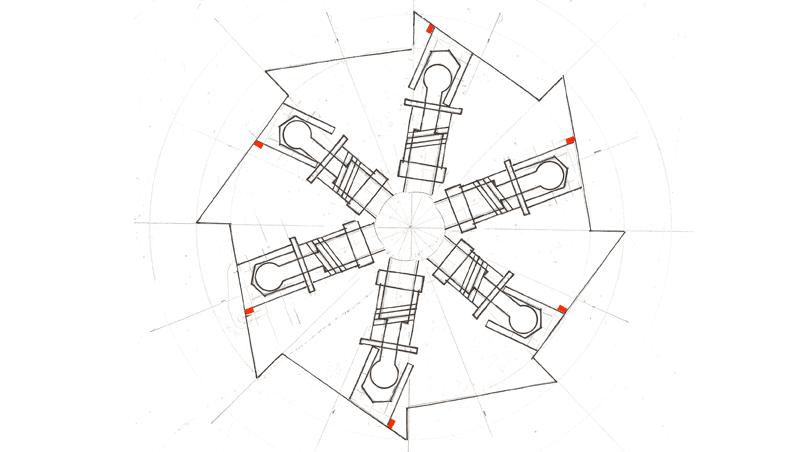

Here's the first drawing==>

The concept is to apply more pressure on one side of a shape within an air compression chamber.

So the red squares are areas of pressure, which don't occur on the other side of the shape,

as the steps mating(wrung) allow the backward pressure face to be culled. Their area in practice ceases to exist.

However this does mean that the feet have to move uphill, and the air pressure will jam them outward,

meaning that inclination has to be overcome.

Would this provide circular movement?

-The thing about this motor, is that requires no more force than compression, it doesn't need relief.

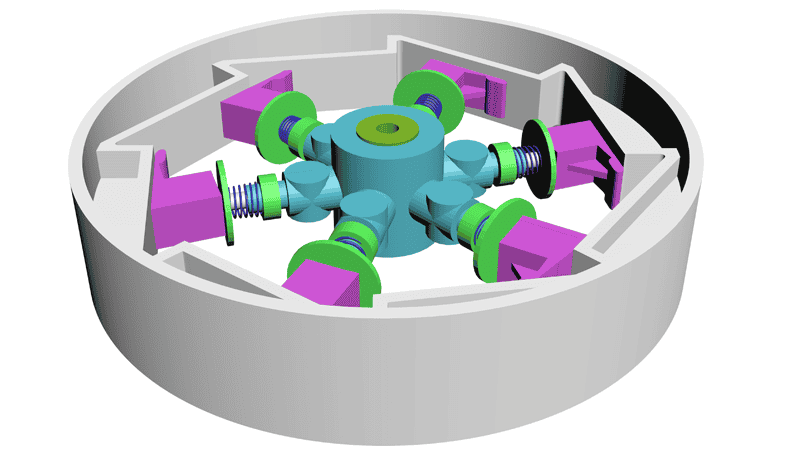

Here's a 3d model:-

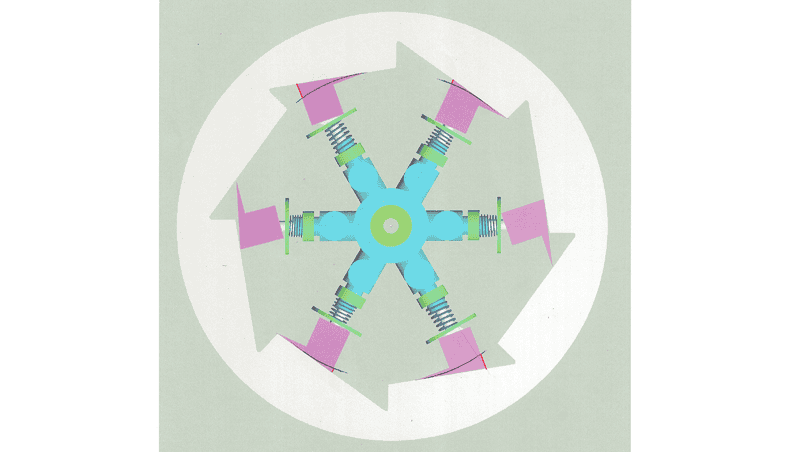

...and the forward pressure areas of such:-

I would like to share, and get this built. Do you think it would work?

...I'd love anyone to get involved

If you'd like to help, please reply with your thoughts

-I hope this is interesting,

if you would just like to comment on why or why this doesn't work,

I'd be curious to hear

Cheers

I want to share my thought on what I have called a 'subducing head',

it's a pneumatic engine.

Here's the first drawing==>

The concept is to apply more pressure on one side of a shape within an air compression chamber.

So the red squares are areas of pressure, which don't occur on the other side of the shape,

as the steps mating(wrung) allow the backward pressure face to be culled. Their area in practice ceases to exist.

However this does mean that the feet have to move uphill, and the air pressure will jam them outward,

meaning that inclination has to be overcome.

Would this provide circular movement?

-The thing about this motor, is that requires no more force than compression, it doesn't need relief.

Here's a 3d model:-

...and the forward pressure areas of such:-

I would like to share, and get this built. Do you think it would work?

...I'd love anyone to get involved

If you'd like to help, please reply with your thoughts

-I hope this is interesting,

if you would just like to comment on why or why this doesn't work,

I'd be curious to hear

Cheers

Last edited: