Matt2015

- 3

- 0

Hello,

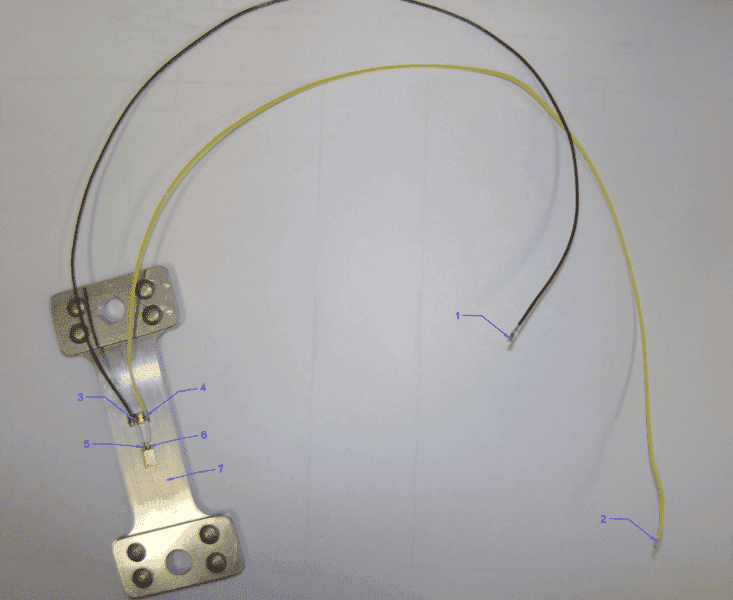

I was wondering if anyone can help me out with this one. I am installing a 350 ohm strain gauge as shown in attached figure. I am expecting to see 350ohm value between terminal 1 and 2. I have checked the values for the following terminals.

1) 5 & 6 = 350ohm (PASS)

2) 3 & 4= 350ohm (PASS)

3) 3 & 2= 350ohm (PASS)

4) 4 & 1= 350ohm (PASS)

5) 5 & 1= 0.03ohm (CLOSED LOOP) (PASS)

6) 6 & 2=0.03ohm (CLOSED LOOP) (PASS)

Any Point (1,2,3,4,5,6) and 7 (Various place on the test strip) = OPEN LOOP (PASS)

1 & 2 = OPEN LOOP (FAIL!) NOT GETTING 350 Ohms

This seems to be unusual problem to have. I have personally tripled checked it. I have asked my friends to check it. Does anyone have an idea what I am doing wrong here.Thanks

I was wondering if anyone can help me out with this one. I am installing a 350 ohm strain gauge as shown in attached figure. I am expecting to see 350ohm value between terminal 1 and 2. I have checked the values for the following terminals.

1) 5 & 6 = 350ohm (PASS)

2) 3 & 4= 350ohm (PASS)

3) 3 & 2= 350ohm (PASS)

4) 4 & 1= 350ohm (PASS)

5) 5 & 1= 0.03ohm (CLOSED LOOP) (PASS)

6) 6 & 2=0.03ohm (CLOSED LOOP) (PASS)

Any Point (1,2,3,4,5,6) and 7 (Various place on the test strip) = OPEN LOOP (PASS)

1 & 2 = OPEN LOOP (FAIL!) NOT GETTING 350 Ohms

This seems to be unusual problem to have. I have personally tripled checked it. I have asked my friends to check it. Does anyone have an idea what I am doing wrong here.Thanks