Guineafowl

- 866

- 404

- TL;DR Summary

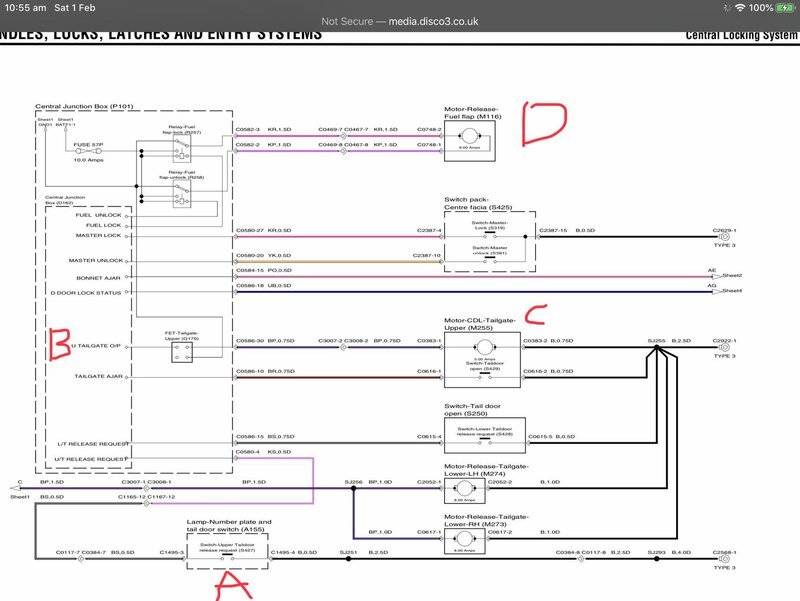

- Intermittent failure of the opening mechanism on my Land Rover Discovery 4 (LR4). I’m trying to work out how the controlling FET is arranged.

Pressing the switch at (A) grounds the “U/T release request” pin of the ECU.

The “U tailgate O/P” pin at (B) then changes state and signals the FET G170.

The connector 586 pin 30 then goes high and powers the tailgate actuator at (C).

If you follow the third pin of the FET, it appears to go to GND1 (I can’t find the follow-on sheet), but is also linked into the fuel flap release motor at D. I suspect GND1 is a switched ground, allowing the fuel flap lock to release or engage, then off.

I assume the fuel flap release motor is involved so that the tailgate may only open if the car is unlocked, changing the state of the controlling relays. What I can’t work out is how the G-D-S pinout of the FET is arranged.

There is only 0.217V to ground at C3007-pin 2 (unplugged) and this does not change when requesting a tailgate open.

I suspect the FET has failed, but it’s extremely hard to get to, so would like to rule out a power feed problem involving the fuel flap relays.

The “U tailgate O/P” pin at (B) then changes state and signals the FET G170.

The connector 586 pin 30 then goes high and powers the tailgate actuator at (C).

If you follow the third pin of the FET, it appears to go to GND1 (I can’t find the follow-on sheet), but is also linked into the fuel flap release motor at D. I suspect GND1 is a switched ground, allowing the fuel flap lock to release or engage, then off.

I assume the fuel flap release motor is involved so that the tailgate may only open if the car is unlocked, changing the state of the controlling relays. What I can’t work out is how the G-D-S pinout of the FET is arranged.

There is only 0.217V to ground at C3007-pin 2 (unplugged) and this does not change when requesting a tailgate open.

I suspect the FET has failed, but it’s extremely hard to get to, so would like to rule out a power feed problem involving the fuel flap relays.